Affordable holographic video displays are possible using surface acoustic waves

Researchers from Brigham Young University (BYU) and MIT believe they have figured out a way to make holographic video displays become larger and more affordable, which could pave the way for 3D video holograms like in Star Wars.

At the moment, true holographic 3D video for consumers is merely a science fiction dream (no, Tupac and Michael Jackson don't count) and the only way to truly experience 3D is to put on a pair of virtual reality goggles, such as Oculus Rift or Samsung Gear VR.

Holograms do exist and are able to render still images but the cost to render recorded video footage or 3D animations is expensive and there is the added problem that using lasers can risk damaging the viewers' eyes.

So instead, the researchers have turned to light, which can be manipulated through reflection, refraction and diffraction.

Diffraction enables almost any type of lines to be bent in order to filter light and it is this property that the researchers have taken advantage of.

A special type of crystal called lithium niobate (LiNbO3) boasts excellent optical properties and beneath the surface of the crystal, microscopic channels, or "waveguides", are created to confine light passing through.

The researchers discovered that by depositing a metal electrode on to each waveguide, it was possible to produce surface acoustic waves that divide the colour frequencies in such a way, a new type of colour display is possible.

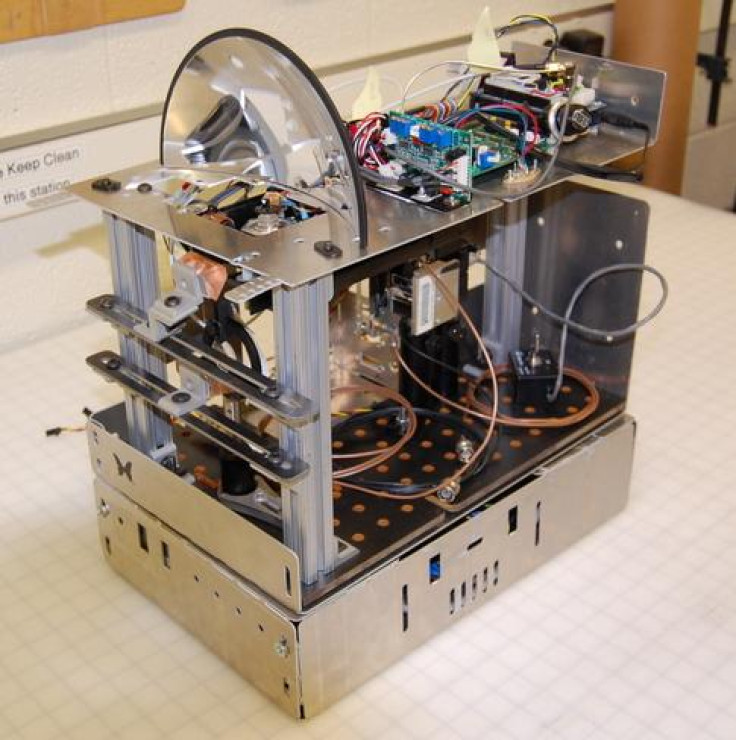

Daniel Smalley, an assistant professor of electrical engineering at BYU, has been working to develop the world's first low-cost holographic video monitor for several years since he was a graduate student at MIT.

"For a wavelength display, we don't need to rely on colour filter wheels or dedicated red and blue pixels," he explained.

Rather than using a colour wheel, the researchers can use surface acoustic waves to create any colour combination they like, just by altering the frequency of the signal sent to the "white waveguide pixel".

"[This means] we can colour the output of our display by 'colouring' the frequencies of the drive signal, [and] as a bonus, this interaction also rotates the polarisation of the signal light so that we can use a polariser to eliminate any noise in the system," he added.

"We can use this technology to make simple and inexpensive colour waveguide displays – including inexpensive holographic video displays. This can drop the cost of a holographic video display from tens of thousands of dollars to less than a thousand."

And if it is possible to make holographic video displays much cheaper, then the technology can be used to make much larger displays, such as room-sized displays.

The study, Frequency Division Color Characterization Apparatus for Anisotropic Leaky Mode Light Modulators, is published in the journal Review of Scientific Instruments.

© Copyright IBTimes 2024. All rights reserved.