Graphene 'industrial revolution': Artificial skin a step closer following production breakthrough

We could be poised for a "graphene-driven industrial revolution" following the discovery of a method to produce the material significantly faster and cheaper than current techniques.

Scientists at the University of Exeter have developed a new way of producing high-quality and low-cost graphene that could one day lead to artificial skin for use in robots.

Research leader Monica Craciun and her team were able to grow graphene in a cold wall chemical vapour deposition (CVD) system – a system based on a concept related to the semiconductor industry. The state-of-the-art machine was developed by graphene company Moorfield.

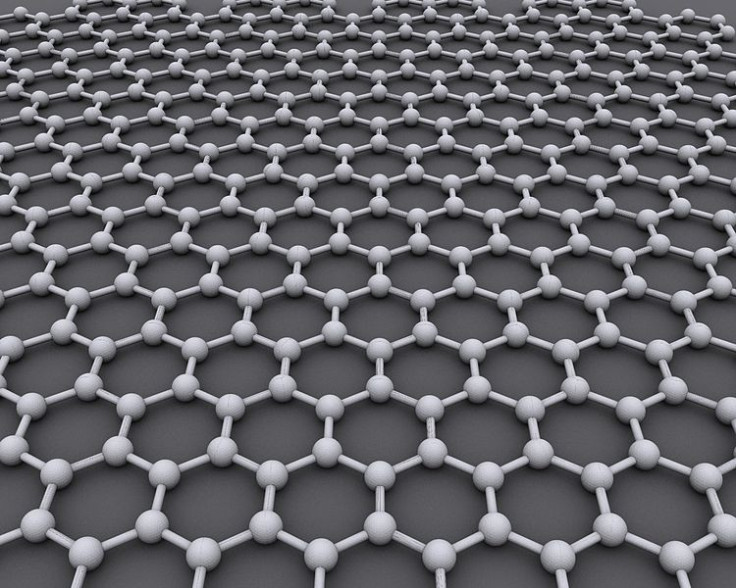

Graphene is known as a wonder material as it is just one-atom thick, but also one of the strongest known materials.

Craciun said: "The vision for a 'graphene-driven industrial revolution' is motivating intensive research on the synthesis of high quality and low cost graphene. Currently, industrial graphene is produced using a technique called CVD. Although there have been significant advances in recent years in this technique, it is still an expensive and time-consuming process."

This is the first time a CVD system has been shown to potentially have the ability to mass produce graphene. It could be used to grow graphene 100 times faster than conventional methods while reducing costs by 99%.

Jon Edgeworth, technical director at Moorfield, said: "We are very excited about the potential of this breakthrough using Moorfield's technology and look forward to seeing where it can take the graphene industry in the future."

Researchers believe the new technique could also be used to create a flexible electronic skin that would revolutionise the robot industry. The findings were published in the journal Advanced Materials.

Saverio Russo, co-author of the study, added: "This breakthrough will nurture the birth of new generations of flexible electronics and offers exciting new opportunities for the realisation of graphene-based disruptive technologies."

© Copyright IBTimes 2024. All rights reserved.