This cool 3D-printing technology could change the colour of your phone case and jewellery

A few minutes of UV light application and you could re-colour your iPhone case to match it with your attire.

3D printing, the process of producing a physical object from a digital model has been around for a long time. Researchers have used this technique to bring amazing ideas to life, but have you seen a 3D-printed object like a phone case that can change colour on demand?

The idea sounds clearly beyond reach, but researchers at MIT CSAIL (Computer Science and Artificial Intelligence Laboratory) are actually making it happen, thanks to a unique tech dubbed ColorFab.

The method, which is still at a nascent stage, lets you print 3D objects that change colour when exposed to ultra-violet light. Meaning anything you print, from a phone cover to a piece of necklace, could be customised as per your choice without having to print them again or buying a new one from the market.

"Largely speaking, people are consuming a lot more now than twenty years ago, and they're creating a lot of waste," said Stefanie Mueller, who led the team that developed the system. "By changing an object's colour, you don't have to create a whole new object every time."

As one could guess, the secret behind the unique colour-changing capabilities lies with the ink — a special one that combines standard dyes and light-adaptable or "photochromic" dyes.

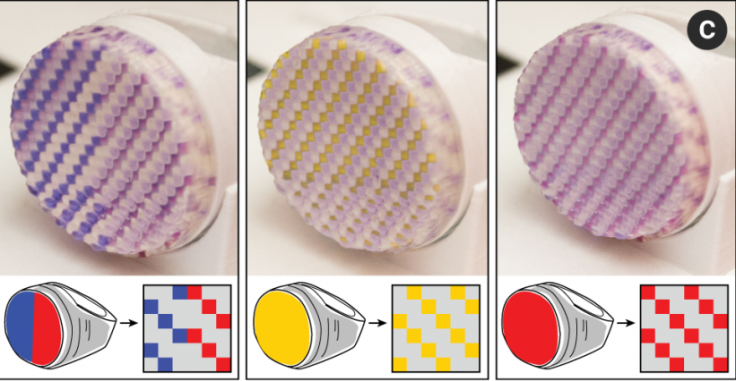

Once you have created the object with a select pattern of colours using ColorFab's interface, you can recolour the whole thing or a specific part of it. All you have to do is select the area you want to customise and then activate the colour in that part with UV light.

As Wired reports, the changed colour stays even when the object is taken out of light and is way better than other colour-changing techniques — limited by single colour or 2D designs — posited so far.

As of now, the whole recolouring process takes about 20 minutes but, Mueller and her team believe they could speed it up with the use of more powerful UV lights or increase the amount of adaptable dye in the special ink mixture.

The work on the new system will be presented at the ACM CHI Conference on Human Factors in Computing Systems in April.