Cheap, fast and safe: 3D-printed bone fixes broken spine of rat and and skull of a monkey

Synthetic graft showed no sign of infection or rejection, with bone growth taking place within weeks.

A 3D-printed synthetic bone has been used to fix the spine and skull of a rat and a monkey. The 'hyperelastic bone' was shown to stimulate new bone growth and integrate with surrounding tissue with no sign of infection or side effects, potentially paving the way for its clinical use in humans.

Scientists from Northwestern University in Illinois were looking to solve problems relating to current research on bone graft materials. These include the expense, the time it takes to produce them, the risk of rejection once implanted, and their being difficult to handle by surgeons operating with them.

To overcome these problems, the team created the hyperelastic bone (HB), which is made from ceramic and polymer already approved for medical purposes.

They combined this with 3D printing technology to create synthetic bone that could be made into a variety of shapes, cut up, and folded to create a custom-made graft in just hours. In one instance, the team showed they could 3D print, wash, sterilize and prepare a human mandible in under three hours.

In the study, published in Science Translational Medicine, researchers led by Adam Jakus used the printed HB to carry out operations in rats and a monkey.

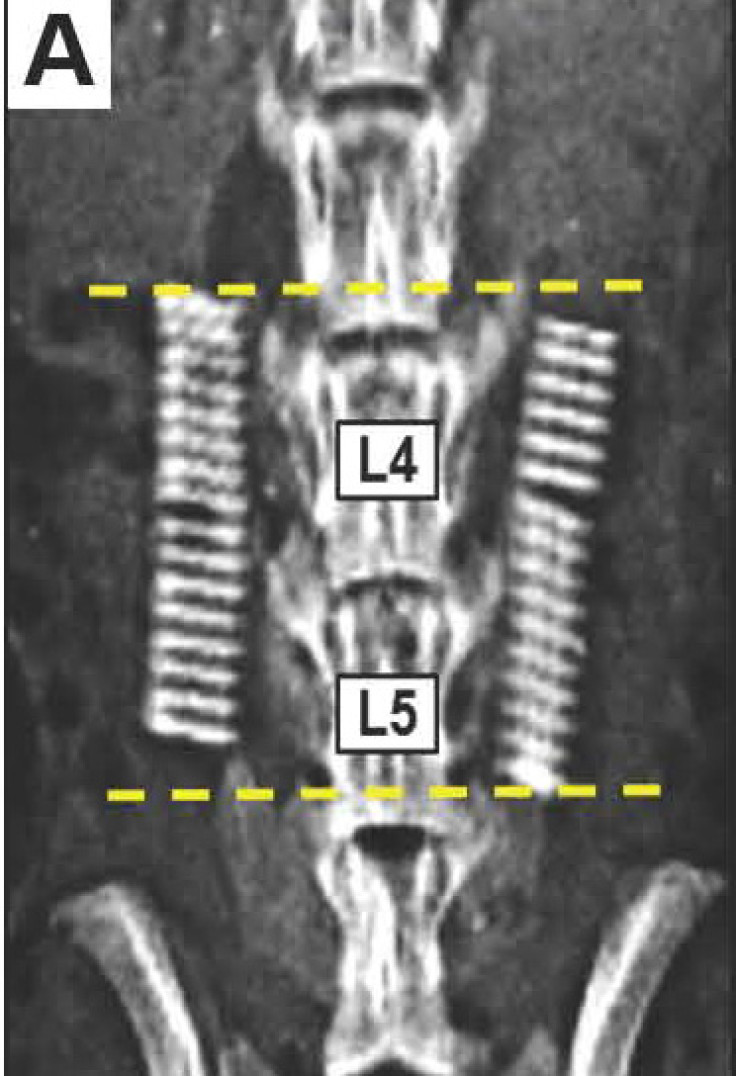

In the rat experiments, the graft was placed into the back bone. Spinal fusion took place, with new bone forming in eight weeks. In a rhesus macaque, HB was used to fix a "large region of weak, unhealthy cortical bone" that had been damaged as a result of electrode implants from other experiments.

In both animal models, HB integrated with the surrounding tissue quickly. Bone was regenerated in rats and it healed the skull defect in four weeks. There were no signs of infection or rejection and bone regenerated without any other biological growth factors (which encourage bone growth).

Researchers say their findings could pave the way to personalised implants for humans as it is low-cost and can be produced on very short time-scales. For humans, it could be used to treat a variety of bone injuries and cancers, as well as providing grafts for reconstructive surgeries.

Concluding, the team wrote: "There is a substantial, ongoing, global medical need for osteogenic biomaterials that are not only highly efficacious but also easy to surgically implement, cost-effective and capable of being manufactured on scales that can address this widespread need.

"With HB, we have demonstrated that well-established, safe, clinically used medical materials can be processed to create new composite material systems ... and that these new systems can potentially be synthesized and manufactured at scales and speeds that are clinically relevant."

© Copyright IBTimes 2024. All rights reserved.