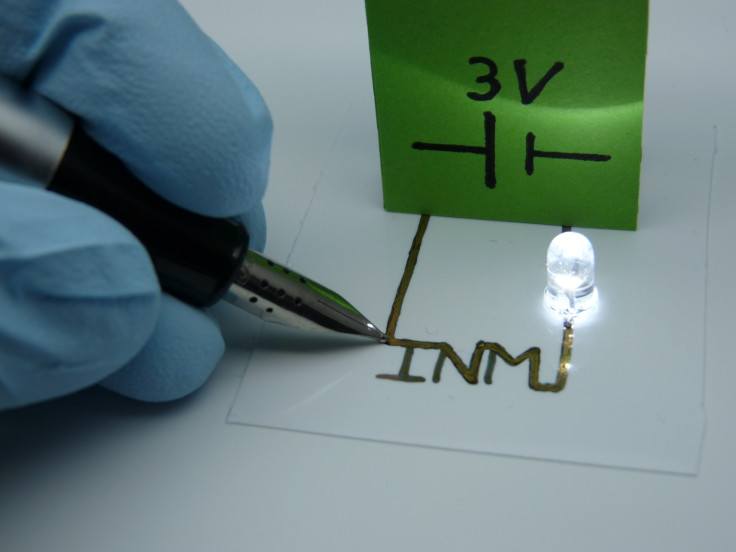

Hybrid ink 'drawable' electonic circuits create radical possibilities for flexible gadgets

Scientists create low-cost functioning electrical circuit technology straight from a pen.

Who said pen and paper was dead? German scientists have developed a new type of ink that allows fully-functioning electronic circuits to be 'written' directly onto a surface from a pen. The technology could provide an inexpensive means of manufacturing printed circuits suitable for flexible smartphones, tablets and other radical gadget designs.

The circuits are ready to be used as soon as the ink dries and requires no additional processing, claim researchers from the Leibniz Institute for New Materials (INM).

Printed electronics are usually created through a process called 'sintering', whereby powdered metals are heated to form conductive electric circuits. Sintering is used to remove organic materials and fuse metal components in electronic inks, but because of the heat involved it can damage materials that are sensitive to high temperatures – for example paper and certain types of plastic.

The new hybrid inks remove the need for sintering altogether, allowing the electronics to quite literally be drawn on to the material.

The inks are made from of gold and silver particles coated with conductive polymers, which are then put into mixtures of water and alcohol.

The addition of the organic polymer compounds are key to the technology as they ensure the metal particles remain in liquid form and ensure they remain arranged during the drying process. They also act as "hinges", allowing the circuits to be bent without losing electrical conductivity.

These properties could therefore make the technology ideal in gadgets requiring high degrees of flexibility and could inspire new form-factors for personal electronics.

The researchers will be demonstrating their results and the potential their new inks offer at this year's Hannover Messe industrial fair on 24–26 April.

© Copyright IBTimes 2025. All rights reserved.