Hydrogen fuel made from corn husks could be renewable energy breakthrough for cars

Researchers from Virginia Tech have discovered a new biological way of creating hydrogen fuel that takes a lot less time and is much cheaper, which could be a breakthrough to help end the human race's dependence on fossil fuels.

Hydrogen fuel is a green fuel that has almost zero carbon emissions, and at the moment, it is produced primarily using high processed sugars. It costs a great deal to produce the gas in large enough quantities for it to be used in fuel cell vehicles, and it is also a challenge just to transfer the gas into fuel cells.

Instead, the Virginia Tech method involves using dirty biomass, i.e. the husks, cobs and stalks of corn plants in order to create the fuel. This means that it is much cheaper to produce the fuel and means that processing plants that make other corn-based products could also make the fuel and use it to power their operations.

Using glucose and xylose simultaneously

The researchers' findings, entitled "High-yield hydrogen production from biomass by in vitro metabolic engineering: Mixed sugars coutilization and kinetic modeling" are published in the journal Proceedings of the National Academy of Sciences (PNAS).

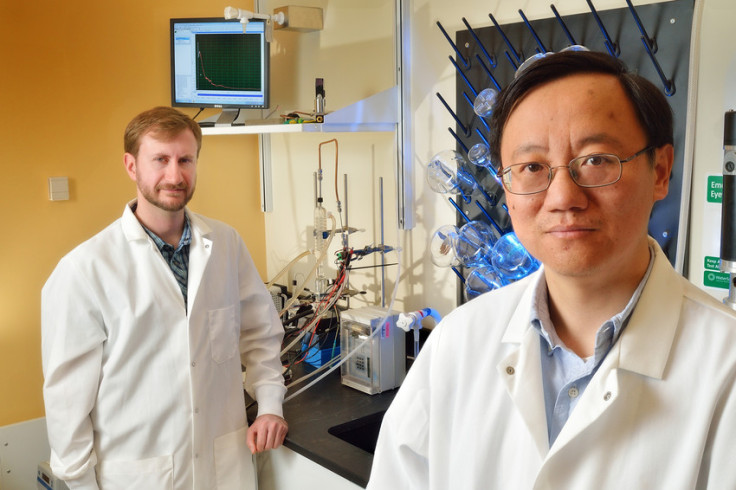

"This means we have demonstrated the most important step toward a hydrogen economy – producing distributed and affordable green hydrogen from local biomass resources," said Percival Zhang, a professor in Virginia Tech's Department of Biological Systems Engineering.

Zhang's former doctoral student Joe Rollin used a genetic algorithm along with a series of complex mathematical expressions to analyse each step of the enzymatic process that breaks down the unwanted parts of the corn plant into hydrogen and carbon dioxide.

He was able to make the system make use of both glucose and xylose at the same time, which increases the rate at which the hydrogen is released. Typically in biological conversions, these two sugars can only be used sequentially, not simultaneously, which adds time and money to the process.

Much faster than hydrogen production today

Using Rollin's method, the new system for creating hydrogen fuel increased reaction rates threefold and the system requires a facility about the size of a petrol station, which is much smaller than hydrogen fuel production facilities today.

Also, by using a cell-free artificial enzymatic pathway, the researchers were able to increase and break the natural limit of hydrogen-producing microorganisms threefold, and also increase enzymatic generation rates so that reaction rates were 10 times faster than the fastest photo-hydrogen production system currently in the world.

The next step for the researchers will be to increase production of the hydrogen fuel using their method to a demonstrable size to prove the costs work out for mass production.

"We believe this exciting technology has the potential to enable the widespread use of hydrogen fuel cell vehicles around the world and displace fossil fuels," said Rollin.

© Copyright IBTimes 2024. All rights reserved.