The Register to Launch First 3D-Printed Rocket-Powered UAV into Space

Technology news site The Register is soon to launch the first ever 3D-printed, rocket-powered drone into space, a hobbyist project solely built by volunteers in the company and interested readers around the world.

Keen to top its existing Guinness World Record for the highest launch of a paper aeroplane, the website has been working on the Low Orbit Helium Assisted Navigator (LOHAN) mission for four years, and it has become a huge crowd-sourced and funded project featuring 30 volunteers from countries such as the UK, Spain, Australia and the US.

This autumn, the LOHAN team will fly to Spaceport America in New Mexico to launch the Vulture 2 unmanned aerial vehicle (UAV) into space.

The spaceplane will be lifted by a helium-filled meteorological balloon to an estimated launch altitude of 20,000m under a carbon fibre launch structure, after which the rocket motor will fire and the aircraft will soar to 25,000m, carrying The Register's trusty mascot "Plucky Playmonaut".

The Vulture 2 unmanned aerial vehicle (UAV) was designed by post-graduate aeronautical design students at The University of Southampton, after which The Register began seeking help from its readers to program the various components in the plane and run test flights.

"It's partly for the fun of it, but the project is also partly to get the readers involved so that we can use that knowledge centrally to build the rocket," Lester Haines, head of The Register's Special Projects Bureau, told IBTimes UK.

"A lot of the stuff we've done has never been done ever, [such as] the high-altitude rocket launch, [which] is particularly challenging. The publishing world is changing and there's a lot more engagement with people. We like to get our readers involved."

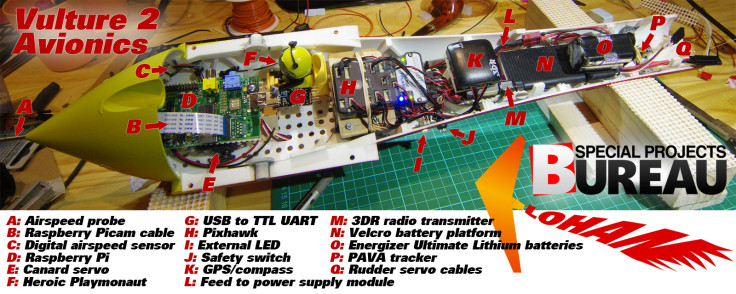

The plane is powered by Raspberry Pi and includes the off-the-shelf 3DR Pixhawk autopilot system by 3D Robotics which enables open-source programming, a camera, a radio tracker, GPS, myriad sensors and of course, a rocket motor.

Originally, The Register was just hoping to lift a spaceplane to altitude and then see what happened if it turned on the rocket, but over time, the mission has now morphed into a colossal project that will see the aircraft return back to Earth, which has required thousands of hours of work.

Apart from a great deal of funding put in by the website, Haines has also had to seek funding from a successful Kickstarter campaign and seek sponsorship from big data analytics company Exosal, big LOHAN fans who have been following the project since its humble beginnings.

Unfortunately, due to the costs of using industrial-scale 3D-printing equipment, there is no test drive for the Vulture 2, only virtual simulators and extensive test flights of the various components at high altitudes to make sure they will survive.

"This plane is not made to be flown at ground level. We've also done a lot of software testing and virtual simulators, so [our high-altitude ballooning specialists] are convinced that it will behave as it should," says Haines.

"I'm confident it's going to work, but then I have to say that."

© Copyright IBTimes 2025. All rights reserved.