Scientists create world's first graphene foam 'wonder material' from a 3D-laser printer

First-of-its-kind technique is breakthrough for mass producing super-strong graphene.

The wonder material that is graphene keeps on getting more wonderful as scientists have managed to successfully create it in a super-strong foam form using a quick and 'simple' 3D-printing method.

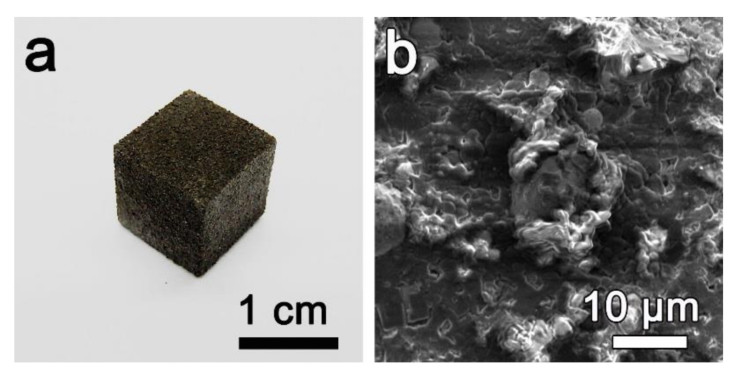

Known to be the first of its kind, the technique saw nanotechnologists from Rice University and China's Tianjin University produce a centimetre-sized cube of the graphene using 3D laser printing, finding a more efficient method of potentially mass-producing the material for industrial applications.

The much-hailed graphene, which is made from pure carbon, is as thin as an atom when in sheet form and has super strength and conductive properties, and researchers are finding even more ways to maximise its ability.

Rice University chemist James Tour, who co-authors the study, began to employ lasers in 2016 to make 3D graphene foam, reinforced by carbon nanotubes to create 'rebar graphene' – a material that is able to support 3,000 times its own weight.

The implications of this discovery could be a massive breakthrough for construction industries, nanoelectronics, more powerful batteries and even bone implants. However, the lengthy process required extreme temperatures and pre-fabricated moulds.

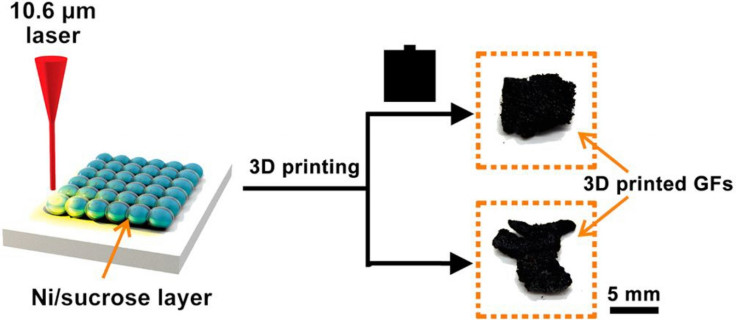

The researchers instead used an adapted technique of common 3D-printing that, rather than creating objects by oozing out molten plastic, fired a beam from a CO2 laser onto a nickel and sugar powder mixture that instantly melts or sinters into a solid slice.

By doing this over and over again, and layering the result the scientists were able to produce a three-dimensional shape. They also found that the process can be conducted at room temperature, eliminating hours of heating and cooling.

"This simple and efficient method does away with the need for both cold-press moulds and high-temperature CVD (chemical vapour deposition) treatment," said co-lead author Junwei Sha.

"The 3-D graphene foams prepared by our method show promise for applications that require rapid prototyping and manufacturing of 3D carbon materials, including energy storage, damping and sound absorption," said co-lead author Yilun Li, a graduate student at Rice.

© Copyright IBTimes 2024. All rights reserved.