Welcome to the space race: Singapore startup creates hybrid rockets and 3D printed fuel to challenge SpaceX

Adam Gilmour sees hybrid rocket engines powered by plastic and wax as the future of space travel.

A Singapore and Australian start-up is building hybrid rocket engines powered by 3D-printed fuel that could revolutionise space travel and challenge Elon Musk's SpaceX ambitions by making it much safer and cheaper to get payloads into space.

This is the brainchild of Adam Gilmour, 42, an Australian former Citibank employee who is now a space tech entrepreneur. He has pioneered the design of a 3D printer that creates 3D-printed space rocket fuel by combining two different materials.

Gilmour, who spent five years teaching himself about space engineering and rocket propulsion and has been living in Singapore for over 20 years, set up Gilmour Space Technologies to develop space rockets powered by hybrid engines and the firm successfully demonstrated a test flight of a small 3.6m-tall demonstrator rocket on 22 July using a hybrid engine and the 3D-printed fuel.

The patent-pending prototype 3D printer was designed by a team of 15 engineers and researchers, aided by a grant from the Singapore government's National Additive Manufacturing Innovation Cluster that helps companies to develop new capabilities in 3D printing.

Although the firm is secretive about the proprietary technology, it says that the 3D printer measures 1m x 1m x 1m, features two extruders – one for ABS or Polyethylene plastic (making it possible to recycle drinks bottles) and one for wax.

Generating a large amount of thrust from hybrid rocket engines

Most big space rocket engines work by burning liquids, usually liquid oxygen with a type of gasoline called RP1, in order to generate the huge amount of thrust required to get a rocket into orbit. The trouble however, is that liquid rocket propellant is still highly combustible and much more expensive.

All engines require a carbon-based fuel that reacts with a liquid oxidiser, but in contrast, the hybrid engine can burn fuel made from plastic or wax, oxidised by hydrogen peroxide.

"We think we can develop big thrust from hybrid engines, that's the game changer because hybrid engines are a heck of a lot easier to design and run than a liquid engine," Gilmour tells IBTimes UK.

"Hybrids are the only rocket engines that don't blow up. If the two chemical compounds mix together, they don't detonate. You would need a lot of heat for them to combust so they're incredibly safe."

GST has offices in both Singapore and Australia and intends to focus primarily on building sub-orbital rockets and well as orbital rockets, starting with a 6 to 8m-tall hybrid sounding rocket with a diameter of between 60cm and 1m that can be used by scientists to test out equipment in space.

South East Asia's answer to Elon Musk

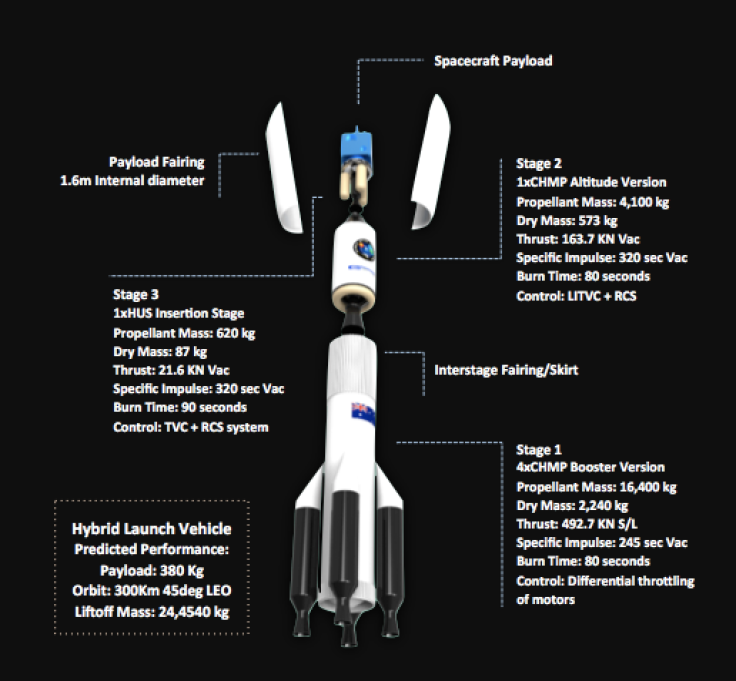

But Gilmour is also confident of being able to build a 22m-tall space rocket with a 1.4m diameter in three years' time that can carry a 400kg payload and will be able to match SpaceX's Falcon 9 rocket's thrust power.

"SpaceX rockets have 9 engines to give 130,000 pounds of thrust. We think we could produce engines that are 100,000 pounds of thrust eventually, and we would be able to print out fuel for our engine from our 3D printer prototype," says Gilmour.

"Our rockets are mostly made from carbon fibre-reinforced plastic, rather than aluminium, which most rockets are made from, so we could probably print 80% of the whole rocket in the future."

The smaller sub-orbital rockets should be ready in 18 months to launch small satellites into space and each launch will likely cost $750,000 (£574,000) rather than $1m, while larger rocket launches will be priced from $5m rather than the $15m charged by other spaceflight companies in the world.

For now, GST is a Singapore and Australian start-up, but all test flights currently have to be carried out in Australia as Singapore does not permit rocket launches, although the Singapore government is considering air or sea rocket launches in the future.

Apart from actively seeking partnerships, Gilmour is also speaking to Nasa about doing a rocket test launch at the Kennedy Space Center in the US, and with Nasa's present focus on revitalising and building a commercial space industry by trying to help private space entrepreneurs, he does not rule out moving to the US.

Gilmour is also working with the Australian Space Academy and hopes to offer space tourism sub-orbital rocket rides that would take 40 minutes, with riders spending about 5-7 minutes in space before returning to Earth.

© Copyright IBTimes 2024. All rights reserved.