The Digital Age of Corrugated: How to Take your Business to the Next Level

Explore strategies and insights as this article delves into leveraging digital technologies for transformative growth in the corrugated industry.

If you've picked up your smartphone only to discover its battery is dead, then you are aware of the power of software – your state-of-the-art phone is effectively reduced to an expensive paperweight.

Through a combination of engineering and design expertise, smartphones continue to get thinner despite containing a myriad of silicon, aluminium and other materials. However, without cooperation between software and hardware, no amount of engineering and design will make that device function. Software is ubiquitous in the technology we use every day.

While the example above is seemingly obvious, the power of software is also becoming increasingly evident in the world of corrugated, as has its ability to improve productivity without needing hardware-based changes; this is helping businesses to achieve more with less. Instead of upgrading old machines, intelligent software effectively utilises existing equipment, reducing the need for costly CAPEX investments.

Look to the corrugated experts

eProductivity Software (ePS) has vast experience in the corrugated industry, with software roots going back to the early 1980s with Corrugated Technologies Inc (CTI) & PC-Topp. ePS has developed a rich portfolio of corrugated software solutions, partly due to acquisitions but fundamentally driven by a desire to create best-of-breed industry-specific solutions.

The corrugated team at ePS is made up of individuals with experience in the corrugated and packaging markets, giving a holistic view of the systems required, as many of the team were themselves, users of the solutions when working in the industry.

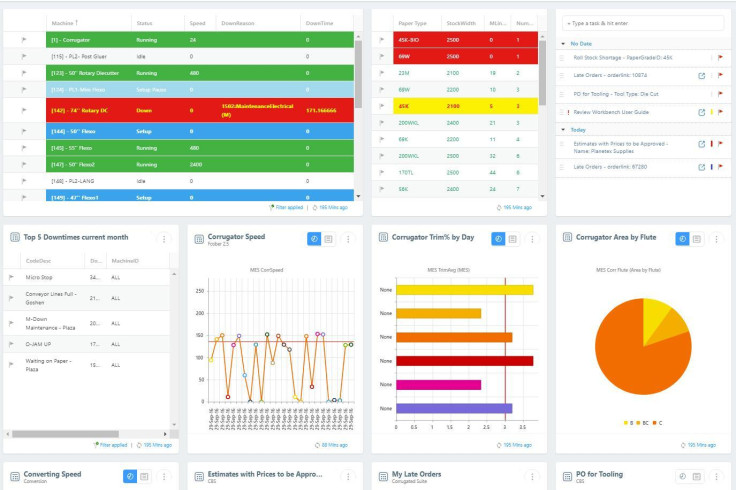

ePS' flagship end-to-end corrugated packaging software offering is the Corrugated Suite, aka CorrSuite; its optimisation solutions have increased its customers' productivity and bottom lines globally.

CorrSuite is designed for corrugated board manufacturers and box converters. It allows customers to increase the profitability of their entire integrated workflow from initial job acquisition through estimating, prepress, scheduling, data collection, job costing, shipping and accounting.

The Corrugated Business System (CBS) is a complete Enterprise Resource Planning (ERP) solution designed specifically for the industry. The product management and commercial estimating components have been built from the ground up, leveraging ePS' 40+ years of experience to ensure it is the best solution in the market today.

CBS provides customers with tools to build highly detailed cost models that allow them to quote prices accurately and confidently to their customers while having complete confidence in the margins and profitability of each product and business unit.

The ePS Manufacturing Execution System is a comprehensive suite of specialised software modules. The system automates manufacturing processes and manages plant floor and customer data, saving customers time and resources. Each module is a reliable, high-performance, cost-saving solution for each unique production environment and incorporates customer service needs.

The level of automation that these modules provide enhances customers' production, management systems and processes and reduces errors resulting from manual inputting of data along all points in the process, from 'order' to 'cash'. By providing real-time visibility into all the operations, these intelligent solutions increase productivity and eliminate wasted time employees spend entering or searching for information.

Schedulers benefit from the flexibility of CorrPlan® & CorrTrim®, which support both pull and push scheduling abilities. CorrPlan is crucial to balance the need for more efficiency.

The tight integration of the module facilitates flexibility in scheduling, giving planners multiple options from which to create the lowest production cost schedules for any given order pool, sequencing effectively by grouping orders and balancing production inventory levels with intelligent scheduling to avoid too much Work-In-Progress (WIP) – allowing businesses to increase the efficiency required to produce a higher volume of products with greater profits.

Another module within CorrSuite is CorrTrac®; it impacts the highest cost of production – paper. CorrTrac is a roll-stock inventory solution that tracks every aspect from ordering to consumption. By utilising CorrTrac in a corrugated plant, board manufacturers can maintain an efficient inventory, ensuring plant floor employees utilise butt rolls, minimise waste and reduce over-ordering of stock.

Complementing CorrTrac is Roll Stock Analysis (RSA), a service offered by ePS to ensure the most efficient use of paper across the plant.

The RSA calculates the plant's existing paper consumption to reduce the number of board grades and paper changes while adjusting the schedule to optimise the most efficient use of roll stock. One customer achieved an annual cost reduction of more than $230,000 – savings not to be sniffed at!

It's worth noting that these solutions can be implemented as part of CorrSuite as a complete solution, or as standalone industry-specific applications that integrate with existing systems and workflows, allowing customers to grow at a pace convenient to them.