This amazing two-atom-thick material becomes so hard under pressure it can stop bullets

When sudden pressure is applied to diamene it temporarily becomes harder than diamond.

To be effective at stopping bullets, modern body armour is often manufactured to be thick and heavy.

However, this may soon be a thing of the past according to researchers from City University New York, who have discovered an ultra-thin material which hardens on impact to be as tough as diamonds.

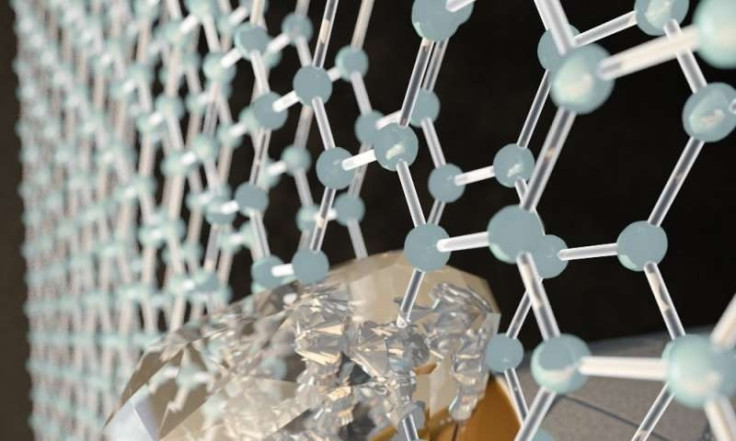

The material is known as diamene is made from two stacked layers of graphene on a base of silicon carbide.

Graphene on its own consists of a single layer of carbon atoms arranged in a honeycomb pattern. It is the world's strongest material and is also a good conductor or heat and electricity, making it useful in numerous applications.

So not surprisingly diamene also displays some fascinating properties. In its regular state it is light and flexible. However, when sudden pressure is applied at room temperature it temporarily becomes harder than diamond – one of the hardest materials on Earth.

"This is the thinnest film with the stiffness and hardness of diamond ever created," said Elisa Riedo, from CUNY. "Previously, when we tested graphite or a single atomic layer of graphene, we would apply pressure and feel a very soft film. But when the graphite film was exactly two-layers thick, all of a sudden we realised that the material under pressure was becoming extremely hard and as stiff, or stiffer, than bulk diamond."

In a study describing the material, published in the journal Nature Nanotechnology, researchers noted how computer models identified this intriguing property of diamene, if the two layers of graphene were aligned precisely with each other.

Intriguingly, when the team tested real samples they found that just two sheets of graphene was the magic number when it came to the hardening effect. Any more or less did not prove as effective.

In future, sheets of diamene could be used to create ultra-thin bulletproof vests or wear-resistant protective coatings.