Graphene Produced Using Kitchen Blender and Washing-Up Liquid

Scientists have developed an innovative and potentially groundbreaking method to produce high-quality graphene of a consistent size and in large amounts.

Micrometre-sized flakes of graphene were obtained from graphite powder - most commonly found in pencil lead - by adding it to a mixture of water and Fairy Liquid and spinning it in a kitchen blender.

The research, recently published in Nature Materials, was led by Professor Jonathan Coleman at the Advanced Materials and BioEngineering Research (Amber) centre at Trinity College Dublin.

"It is a significant step forward towards cheap and scalable mass production," said Andrea Ferrari, an expert on graphene at the University of Cambridge.

What is graphene?

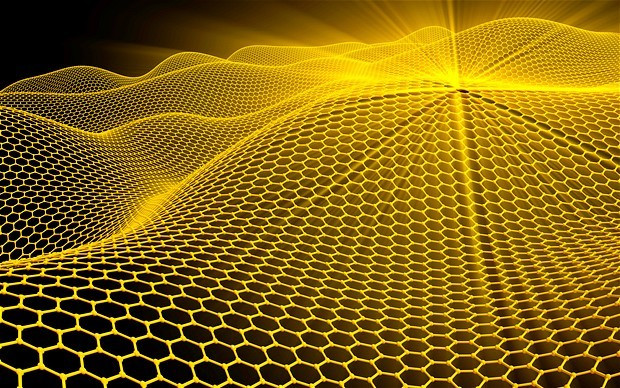

Graphene is a one-atom-thick material made of carbon atoms arranged in a honeycomb lattice that is 200 times stronger than steel, more conductive than copper and as flexible as rubber.

"The material is of a quality close to the best in the literature, but with production rates apparently hundreds of times higher."

Commercialisation and applications

Graphene was discovered in 2003 using an equally unconventional method. Scientists Andre Geim and Konstantin Novoselov from the University of Manchester were able to isolate the one-atom thick material using sticky tape on the nib of a pencil.

The discovery earned the pair a Nobel Prize in Physics in 2010, however attempts to mass-produce the material have so far proved notoriously difficult.

Previous breakthroughs, most recently by researchers at Samsung, have had implications on the production of flexible smartphone screens, while the AMBER team's discovery is currently being tested as the electrode materials in solar cells and batteries.

"The graphene market isn't one size fits all," said Coleman, suggesting that the flakes could also have applications in the manufacturing of plastic bottles and in the creation of a conductive rubber band.

Thomas Swan, a UK-based manufacturer, has partnered with AMBER to scale-up the production process to produce a kilogram of graphene a day by the end of the year.

Coleman has predicted that the number of firms currently trying to commercialise graphene production will shrink as certain production techniques are adopted.

"Most of the companies are selling stuff that I wouldn't even call graphene," Coleman said. "There are many companies making and selling graphene now; there will be many fewer in five years time."

© Copyright IBTimes 2025. All rights reserved.