Scientists Create Self-Healing Regenerative Plastic

Researchers at the University of Illinois have managed to develop a type of plastic that is able to heal and completely regenerate all by itself, which could be a big benefit in situations where products are difficult to repair or replace, such as a part of an aeroplane or vehicle.

The team of researchers, led by Professor Scott White at the The Beckman Institute for Advanced Science and Technology, have created a brand new system that imitates the way blood clots form in biological circulatory systems, taking a vascular approach whereby non-living, synthetic materials contain networks of capillaries that can jump into action when the material is damaged, even if it happens more than once.

Their research paper, entitled "Restoration of Large Damage Volumes in Polymers" is published in the journal Science.

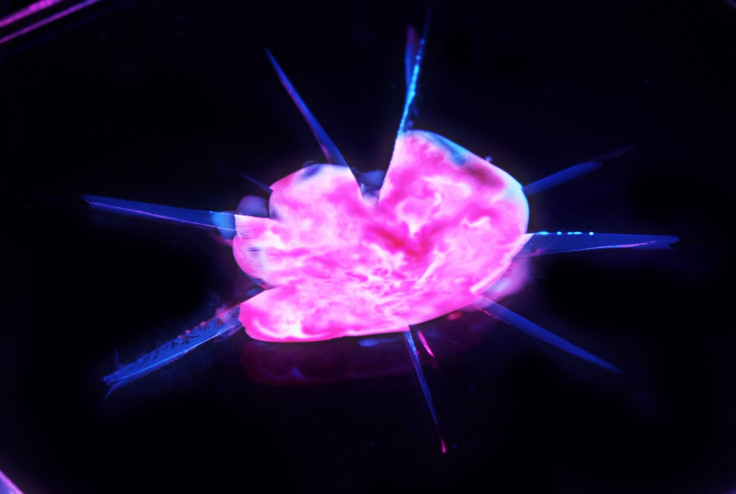

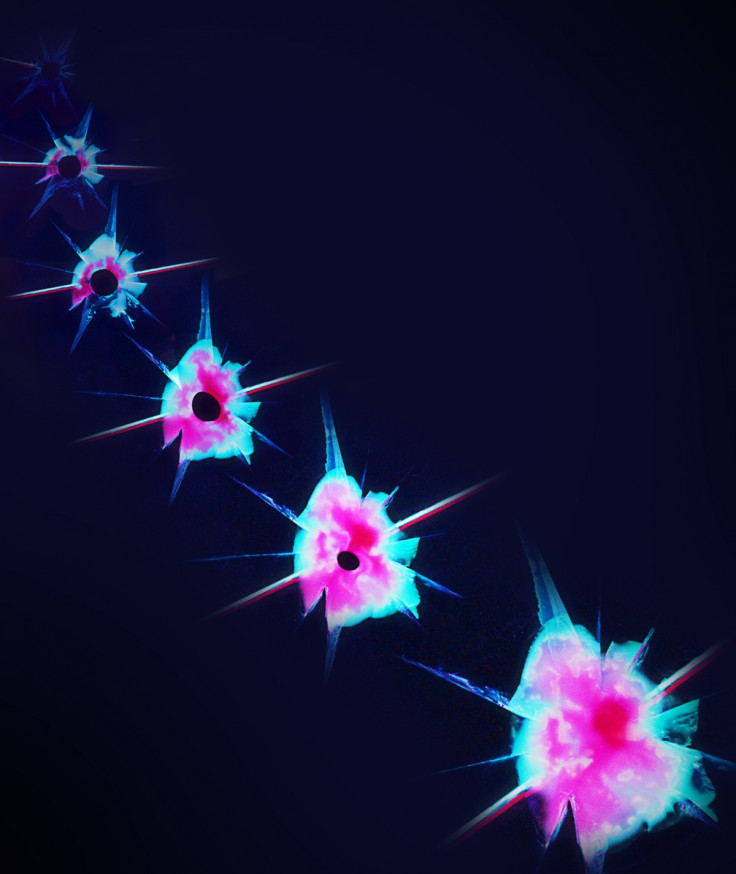

Until now, self-repairing materials have only been able to bond microscopic cracks. With the new system, if the plastic is damaged, regenerative chemicals flow out from two adjoining, parallel capillaries.

When the two liquids mix together, they form a gel that is able to fill in any cracks or holes caused by the damage and then harden within a few minutes into a strong polymer, which is able to completely restore the plastic's mechanical strength.

"What's important about our approach is that we've been able to isolate the chemical components for two separate reactions to occur simultaneously, into very stable channel networks," explains White in the video.

"One of the critical features that we have been able to demonstrate is that we have the ability to tune the kinetics of these reactions independently, so we can speed up the gelation reaction or slow it down. We can also speed up or slow down the hardening reaction to allow you to recover structural materials."

The researchers tested their regenerating system out on thermoplastics and thermosets, which are two of the most commonly used plastics.

Even if the damage is caused by a bullet hole, which sets off a radiating series of micro cracks, by being able to slow down or speed up the gel's hardening reaction, the gel will have time to seep into the cracks before hardening.

"One of the most exciting things about the kind of work we're doing right now is that regeneration is just the first step towards the ultimate goal, which is to have a material system that continually remodels and regenerates itself.

"So just like the way that human bones remodel throughout your lifetime, we could see engineering structures that continuously regenerate and perhaps extend their lifetime beyond our wildest dreams."

© Copyright IBTimes 2025. All rights reserved.