'Super wood' created that is stronger than steel and can stop a speeding bullet

Lightweight alternative to steel in construction, vehicles and bulletproof armour.

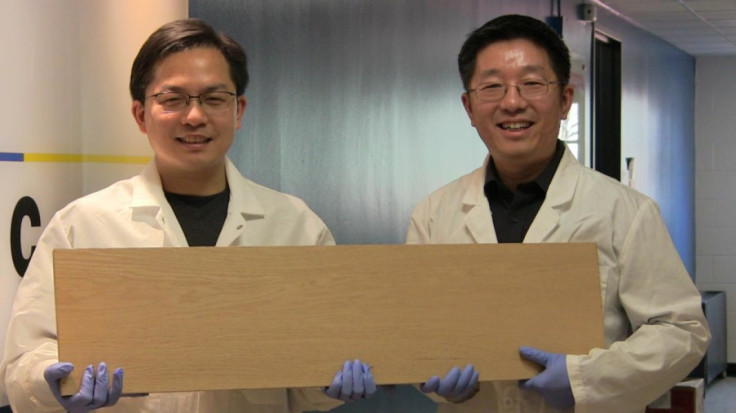

Materials researchers have developed a simple process that can turn a piece of wood into an ultra-compact material that is as strong as steel and can even stop bullets.

Although wood is versatile, abundant and relatively cheap to produce, scientists have long tried to make it even more useful by attempting to enhance its strength to the level of metals. One way of doing this was by compressing it, but "densified" woods have a tendency to weaken, especially in high humidity.

The inexpensive new technique, created by a team from the University of Maryland and described in a paper published in the journal Nature, involves boiling a wooden block in a solution of sodium hydroxide and sodium sulphite, which removes substances that give it rigidity.

The wood is then simultaneously compressed at high pressures and heated to 100C.

The resulting material is 20% smaller, three times denser and has a number of impressive properties: It is 20 times more rigid, 50 times more resistant to compression and can withstand 11.5 times more stretching and pulling – making it as strong as steel, albeit lighter.

Not only is it significantly more scratch and impact-resistant than the original wood, it is also moisture-resistant and can be moulded into almost any shape during the compression process.

The densified wood can even stop bullets, according to the researchers. In the study, they fired stainless steel pellets from an airgun which easily penetrated a normal wooden plank but did not break through an equal thickness of stacked layers of the treated wood.

The team say the technique could lead to a whole new class of strong, lightweight wooden materials that could be used to replace steel in construction, build lightweight and efficient vehicles or even produce bullet-resistant armour plating among other applications.