Global Energy Crisis: Belgian Scientists Succeed In Turning Sawdust into Petrol

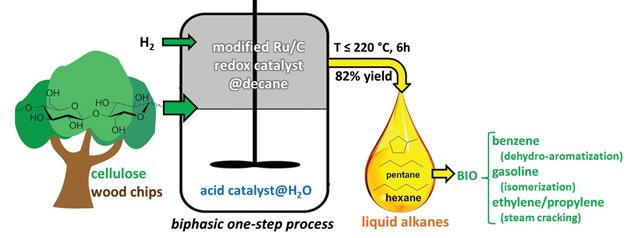

Scientists at Katholieke Universiteit Leuven (KU Leuven) in Belgium have succeeded in converting the cellulose in sawdust into hydrocarbon chains, an important additive in petrol (gasoline) and plastics, which could potentially provide a solution to the global energy crisis.

Cellulose is an organic compound obtained from wood pulp, straw, grass and cotton that is used to make cardboard and paper.

Since cellulose contains strong carbon chains, the researchers were able to remove the oxygen bonded to these carbon chains, thus creating a product that only requires one simple step before it can become fully-distilled petrol.

The research, entitled Direct catalytic conversion of cellulose to liquid straight-chain alkanes is published in the journal Energy & Environmental Science.

"Essentially, the method allows us to make a 'petrochemical' product using biomass – thus bridging the worlds of bio-economics and petro chemistry," said Dr Bert Lagrain, co-author of the study and a researcher at KU Leuven's Centre for Surface Chemistry and Catalysis.

"We have also built a chemical reactor in our lab: we feed sawdust collected from a sawmill into the reactor and add a catalyst – a substance that sets off and speeds the chemical reaction.

"With the right temperature and pressure, it takes about half a day to convert the cellulose in the wood shavings into saturated hydrocarbon chains, or alkanes."

The researchers currently have a patent pending for their new method of bio-refining, which can stretch beyond producing just gasoline to other types of materials.

"Our product offers an intermediate solution for as long as our automobiles run on liquid gasoline. It can be used as a green additive – a replacement for a portion of traditionally-refined gasoline," said Professor Bert Sels, co-author of the study who is also part of the Centre for Surface Chemistry and Catalysis.

"The green hydrocarbon can also be used in the production of ethylene, propylene and benzene – the building blocks for plastic, rubber, insulation foam, nylon, coatings and so forth."

The best thing about cellulose is that it is a cheap, easily available compound, and thus could be hugely useful to European countries, where there is a shortage of crude oil and it is difficult to easily produce shale gas.

"From an economic standpoint, cellulose has much potential. Cellulose is available everywhere; it is essentially plant waste, meaning it does not compete with food crops in the way that first generation energy crops – crops grown for bioethanol, for example – do," said Sels.

"It also produces chains of 5 to 6 hydrocarbon atoms – 'light nafta' in the technical jargon. We are currently facing shortages in this because it is becoming quite difficult and more expensive to distil these specific hydrocarbon chains from crude oil or shale gas. In time, hydrocarbon derived from cellulose may provide an alternative."

© Copyright IBTimes 2025. All rights reserved.