The Hidden Costs of Manual Testing for Manufacturers

From hidden labour costs to compliance risks, outdated manual methods are draining pharmaceutical and food manufacturers

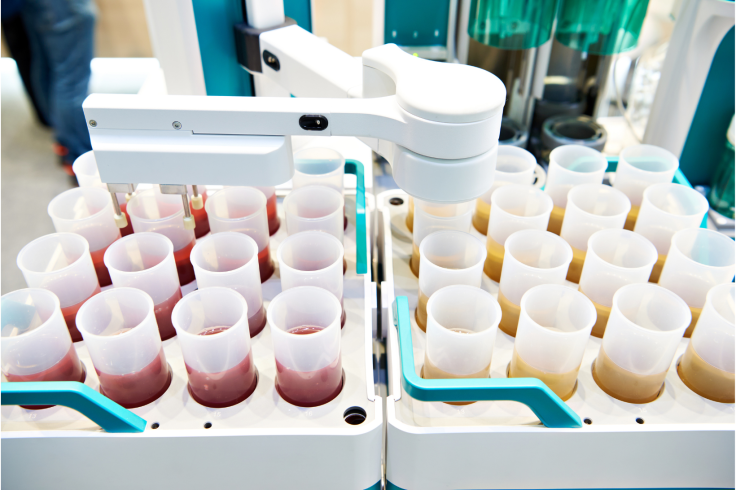

Titration remains a trusted method for ensuring quality in pharmaceuticals, food, and chemicals, core industries where precision and compliance are essential.

Beyond reagents and equipment, manual testing incurs hidden costs. Skilled technicians must repeat time-consuming tasks, and even minor human errors can trigger product rejections or

rework. Labs that adopt automated titration systems report fewer inconsistencies and significantly reduced turnaround times. Regulatory demands also increase documentation burdens.

These challenges have pushed companies to reassess their titration workflows. Manual processes - like handwritten records, repeated checks, and regulatory catch-ups - consume time and increase the risk of delays. Small errors or slowdowns can escalate into significant costs.

The Financial Impact of Manual Titration Methods

Manufacturers often focus on equipment and reagents, but manual titration brings added costs: ongoing labour, higher risk of human error, and regulatory burdens.

Labour represents a major portion of testing costs. Technicians handle every step manually, from measuring to recording, requiring full attention, especially during complex analyses. For facilities seeking efficiency improvements, a modern titrator for chemistry labs can dramatically reduce these labour demands.

Error rates can also contribute to financial challenges. Even experienced technicians may make mistakes without the aid of automated checks. Each error can lead to consequences such as wasted materials and production delays. In pharmaceutical manufacturing, a single batch rejection can result in substantial losses in materials alone.

Regulatory compliance adds yet another layer of cost. Manual documentation increases the risk of incomplete records, which may result in regulatory findings during audits. Addressing these regulatory matters can involve fines, remediation costs, and production interruptions.

Quantifying Labour Expenses in Laboratory Testing

Labour costs related to manual titration can increase quickly when accounting for technician salaries, time requirements per test, and operational practices. Since manual testing is time-intensive, total salary costs can become substantial annually. When overtime, shift allowances, and management oversight are considered, the full expense rises further. Manual titration often requires multiple rounds of quality checks, significantly extending technician time and effort.

Specialised skills further increase these costs. Manual titration requires specific chemistry knowledge and analytical abilities, often commanding higher pay rates than standard production roles. Qualified laboratory technicians generally earn more than general manufacturing personnel.

Training expenses add to this financial burden. New technicians may require several weeks of intensive training before performing independent analyses, representing both direct costs and lost productivity. With industry turnover rates, these training cycles can repeat frequently.

Staff retention presents ongoing difficulties. The repetitive nature of manual testing can lead to burnout and turnover. Replacing a skilled technician may be costly when accounting for recruitment, training, and temporary productivity losses.

How Automation Transforms Laboratory Economics

The difference between manual and automated titration becomes most evident in how many samples each can process daily. While manual methods typically process fewer samples per day per technician, automation improves productivity, allowing laboratories to process more samples with the same staff.

Reagent consumption falls with automation. Automated titrators for chemistry labs deliver precise volumes with minimal waste, reducing chemical usage and helping to lower waste management fees. This precision supports direct cost savings for laboratories.

As routine testing shifts to automation, staff can be reallocated. Technicians can focus on more advanced analytical work, method development, and improvement projects, making better use of their skills and improving laboratory operations.

Modern titrators provide detailed analytical data that helps adjust processes. For facilities considering ways to manage costs and increase efficiency, automation provides digital traceability while supporting compliance.

Case Study: Manufacturing Quality Control Transformation

A UK pharmaceutical manufacturer demonstrates the benefits of automation. After implementing automated titration systems, their quality control laboratory reported a reduction in testing turnaround time from 48 hours to just 6 hours. Digitisation significantly reduced quality-control release time, enabling faster batch releases and increased production capacity.

Efficiency metrics showed major improvements. The company reduced laboratory staffing requirements while increasing test volume. These freed resources were redirected toward developing and validating new methods, creating further advantages.

Company reports indicated better result consistency and reliability following automation, leading to fewer errors and quicker decision-making. Gains in testing accuracy and shorter turnaround have been named as key elements in the company's ongoing quality strategy.

Data Integrity Challenges in Manual Testing Environments

Documentation errors represent a considerable risk in manual testing. Handwritten laboratory records often contain mistakes, such as incorrect figures or missing information, any of which can harm data reliability. Without consistent electronic records, even basic transcription errors may go unnoticed until batches are delayed or questions arise during audits.

Manual record keeping often creates traceability obstacles. Auditors require detailed records showing who performed tests, when, and using what methods. Manual processes frequently struggle to maintain this chain of evidence, revealing compliance gaps.

Audit preparation can become particularly time-consuming with paper records. Quality teams may spend many hours gathering and organising documentation for inspections, representing a substantial hidden cost.

Automated titrators generate complete, secure digital records that meet compliance standards, capturing all test parameters and eliminating transcription errors.

Future-Proofing Quality Control Processes

Industry developments show increasing adoption of automated testing across manufacturing sectors, reflecting their effectiveness in modern production environments. Integration capabilities with manufacturing execution systems offer benefits and allow seamless data transfer between quality control and production.

Scalability becomes important as production grows. Automated systems increase testing capacity without proportional increases in staffing or laboratory space, supporting expansion without bottlenecks.

Training requirements for transitioning to automated workflows are often brief. Most technicians become proficient with automated systems within a short period, minimising operational disruption during the transition.

Maintenance considerations favour automated systems due to extended lifespans. Modern titrators are generally designed to operate for many years with routine servicing, and future scalability can further extend their long-term cost-effectiveness.

Implementing Change Management for Testing Protocols

Staff resistance can arise when introducing new technology. Laboratory teams may express concern about job security or reliability. Including teams early in the process and addressing their concerns openly is key to successful adoption.

Phased rollout strategies help avoid operational disruption. Introducing automation with less critical tests allows teams to build familiarity and confidence with new systems before expanding to essential analyses. This method maintains quality standards while guiding gradual change.

Improvements

By centralising tasks and minimising errors, automation reduces labour demands and boosts efficiency. Despite upfront costs, labs save over time through lower overtime, reduced reagent waste, and fewer repeated tests.

Manual titration may still serve its purpose, but the hidden costs - from labour to compliance risks - are too significant to ignore. Automated systems offer faster turnaround, fewer errors, and more efficient use of resources. For manufacturers aiming to stay competitive, upgrading their testing protocols isn't just a technological decision, it's a strategic one. Automation ensures long-term resilience in both quality control and operational performance.

About the author: Jess is an experienced writer who has contributed to various platforms, covering topics ranging from business and technology to lifestyle, travel, and education. With a desire to create clear and engaging pieces for the reader, she enjoys exploring new subjects and crafting content that resonates with readers. Over the years, she has aimed to make complex ideas easy to understand and enjoyable to read.

© Copyright IBTimes 2025. All rights reserved.