IBM's ultra powerful computer chip puts Moore's Law back on track

IBM has announced a computer chip that has four times the capacity of today's most advanced chips, keeping the advances of Moore's Law on track until at least 2018.

Moore's Law observes that the number of transistors on a computer chip double every two years. This exponential progress in processor technology has seen computers shrink from the size of entire rooms, to devices that can fit in a pocket.

The rule has begun to fall apart in recent years, however, as the limitations of silicon as a semiconductor are reached. The main issue is that it is not possible to reliably scale down silicon chips below 10 nanometres.

In order to create chips with transistors below 10 nanometres, IBM used silicon-germanium instead of pure silicon in certain regions of the chip. The research advance also indicates that the new material could be used to create more powerful chips in the future.

"This is a welcome sign for the chip industry," said Envisioneering analyst Richard Doherty. "You can count on at least two more turns of Moore's Law benefits.

"This puts IBM in the position of being a gentleman gambler as opposed to a horse owner. They still want to be in the race."

Working in a consortium with GlobalFoundries, Samsung and SUNY (State University of New York), IBM is targeting "at least a 50% power/ performance improvement for the next generation of systems".

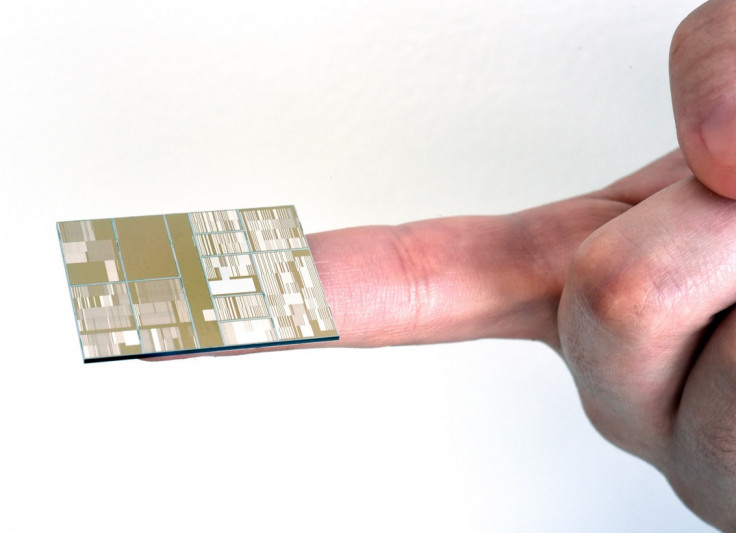

The seven nanometre transistors used in the chips are more than a thousand times smaller than the diameter of a red blood cell, and only three-times larger than the diameter of a strand of DNA. It is expected to be another 10 years before the chip is commercially available.

IBM is also looking at the possibility of using a 3D chip stack that utilises carbon nanotubes to vastly improve computer chips. The firm announced in 2014 that it is aiming to build commercial transistors using carbon nanotubes by 2020.

© Copyright IBTimes 2025. All rights reserved.