Low-Cost and Colourful LEDs Made from Wonder Material Perovskite

Perovskites That Are Used to Make LEDs Are Known as Organometal Halide Perovskites

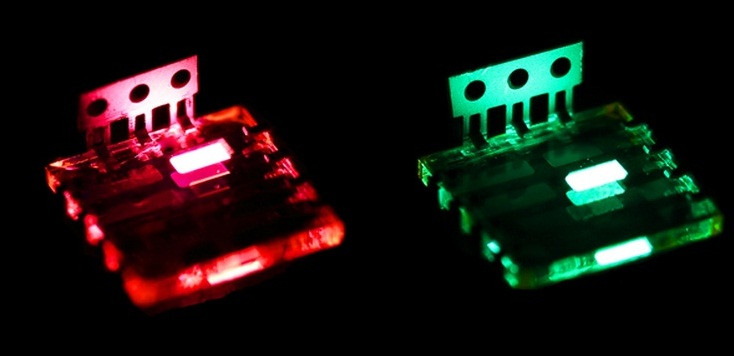

Low-cost and colourful LEDs (Light-Emitting Diode) have been manufactured from a material known as 'perovskite,' potentially opening up a wide range of commercial applications.

Researchers from the University of Cambridge, University of Oxford and the Ludwig-Maximilians-University have demonstrated an application for perovskite materials to make high-brightness LEDs.

Perovskite

Perovskite is a group of materials having distinctive crystal structure of cuboid and diamond. Owing to their superconductivity and ferroelectric features, these can be used to convert light into electrical energy, according to a report by University of Cambridge.

This is the same perovskite that has been recently found to make efficient solar cells, which could replace silicon.

LED from Perovskite

The kinds of perovskites used to make LEDs are called 'organometal halide perovskites'. These contain a mixture of lead, carbon-based ions and halogen ions called halides. These materials dissolve well in solvents and when dried, are assembled to form perovksite crystal.

"These organometal halide perovskites are remarkable semiconductors. We have designed the diode structure to confine electrical charges into a very thin layer of the perovskite, which sets up conditions for the electron-hole capture process to produce light emission," said Zhi-Kuang Tan, a PhD student at the University of Cambridge's Cavendish Laboratory.

"It's remarkable that this material can be easily tuned to emit light in a variety of colours, which makes it extremely useful for colour displays, lighting and optical communication applications. This technology could provide a lot of value to the ever growing flat-panel display industry," Zhi-Kuang added.

How to make LEDs from Perovskite

The perovskite LEDs are made through a simple process in which a perovskite solution is prepared and spin-coated onto the substrate. This particular process does not require high temperature heating steps, while making it cheap to manufacture in large amount. The general methods for manufacturing LEDs, in the contrary, are expensive.

© Copyright IBTimes 2025. All rights reserved.