Electricity: New Technique Delivers High Output Power From Mechanical Motion

Scientists at VTT Technical Research Centre of Finland have demonstrated a new technique for generating electricity by harvesting vibrations from mechanical motion.

Unlike existing energy harvesters, this one does not require an external power source. The VTT harvester can be operated as a charge pump that pushes charge and energy into an energy storage element to deliver high output power.

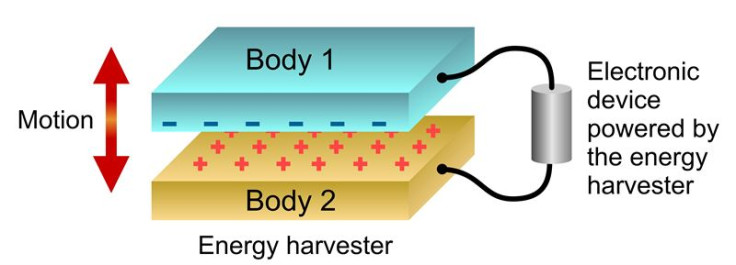

The harvesters used by VTT are similar to electrostatic energy harvesters, based on electrically charged capacitors, the capacitance of which is varied by mechanical motion.

In both, the mechanical energy is converted into electric energy of the capacitor, i.e., external force is performing work to increase the distance between charge on individual plates and thereby increasing the total potential energy of the charges.

But unlike the electrostatic types, the work function harvester used by VTT does not need an external power source or electret materials that pose fabrication and lifetime challenges, says VTT.

Work function is the amount of energy needed to remove an electron from a solid and varies for different materials.

When two different materials with different work functions are brought close to each other and connected through a circuit, charging occurs naturally without any external source as the system aims for a state of equilibrium.

Another unique feature of the work function harvester is that it can be operated in a charge shuttle mode, not possible with electrostatic harvesters, says the study published in Scientific Reports.

This mode can provide extremely large maximum capacitance and, therefore, high output power.

Finally, the comparison of work function and electrostatic energy harvesters showed that work function energy harvesters can generate more power than the electrostatic harvesters in many operating conditions.

Research into energy harvesters that turn mechanical vibration into electricity has focused on piezoelectric and electrostatic devices, which require a battery or piezomaterial.

Energy harvesters are needed in low power electronic devices like wireless self-powered sensors and medical implants, where they could ultimately replace batteries.

© Copyright IBTimes 2025. All rights reserved.