IoT in Manufacturing: Complete Guide with Key Use Cases

How IoT is turning factories into intelligent, self-optimizing ecosystems that predict failures, boost efficiency, and give manufacturers an unbeatable competitive edge.

Remember when factories were all about oil stains on the floor, mechanical conveyors, and workers manually checking every part? Those days are disappearing faster than VHS tapes. Modern manufacturing floors look like something straight out of a sci-fi movie data flowing everywhere like a new kind of raw material, and machines having conversations you're not invited to.

Welcome to the era of smart manufacturing IoT, where factories don't just produce goods — they think, learn, and predict their own future. According to McKinsey, IoT can boost manufacturing productivity by 25% and slash maintenance costs by 40%. We're talking about a complete game-changer that separates market leaders from companies desperately trying to keep their heads above water.

The shift to Industry 4.0 isn't just about slapping more sensors on everything and calling it a day. It's about creating interconnected ecosystems where machines actually talk to each other, analytics happen in real-time, and automation finally works without turning into complete chaos.

What is IoT in Smart Manufacturing?

Let's talk about Rolls-Royce. No, not the cars your neighbor dreams about the jet engine manufacturer. Way back before IoT became the buzzword du jour at every tech conference, Rolls-Royce was already cooking up something revolutionary. They started embedding thousands of sensors into their aircraft engines, collecting over 70 trillion data points from engines humming away on airlines worldwide.

Here's where it gets really interesting: Rolls-Royce basically said 'screw it' to selling engines the old-fashioned way. Instead, they flipped to selling 'power by the hour' a service model where they maintain engines predictively. They swap out parts before failure even becomes a risk, optimize performance from their desks in Derby, and basically turned a product into a subscription service. (Yes, even jet engines have gone the Netflix route.) This shift from hawking equipment to selling outcomes gave them a competitive edge sharper than a turbine blade.

But what does this actually mean when you strip away the corporate speak?

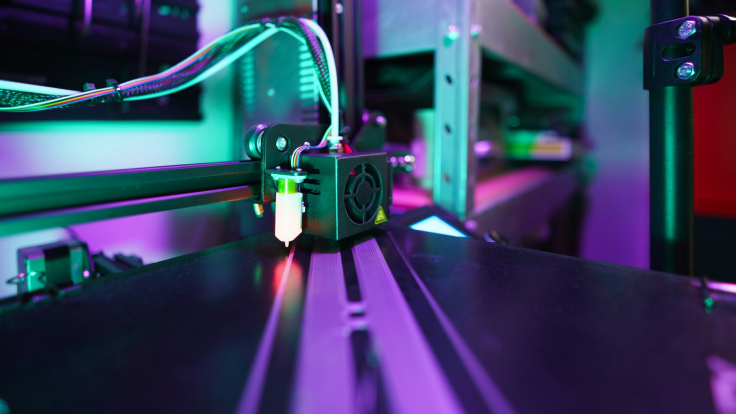

Key components of an IoT ecosystem:

- Sensors — think of them as nerve endings, constantly measuring temperature, vibration, pressure

- Cloud platforms — the brain of the operation, crunching numbers and making decisions

- Analytics tools — basically the consciousness, spotting patterns and predicting what's coming next

Companies like Siemens, Bosch, and GE Digital have turned this integration into an art form. Siemens uses IoT in smart manufacturing to optimize energy consumption across entire facilities (we're talking industrial-scale penny-pinching). Bosch monitors quality with the precision of a Swiss watchmaker on Adderall. And GE Digital's Predix platform transforms industrial equipment into smart assets that practically maintain themselves which is both impressive and slightly terrifying if you've seen enough sci-fi movies.

Smart manufacturing means machines adapt, learn from mountains of data, and make decisions that actually get better over time. It's the difference between a calculator and something that might pass the Turing test.

Next Step: Smart Ecosystems and Data-Driven Collaboration

Manufacturing used to be beautifully linear: suppliers shipped materials, factories made stuff, customers bought it. Simple, predictable, and increasingly about as relevant as a floppy disk. Today's manufacturing landscape looks more like a living organism, a messy, interconnected web where partners, suppliers, and customers are all plugged into the same data streams.

Let's look at five companies actually pulling this off:

1. DXC Technology

DXC Technology specializes in building 'smart connected manufacturing' ecosystems that somehow make legacy systems play nice with cutting-edge IoT infrastructure. Their whole deal is end-to-end digital transformation connecting dusty shop floor equipment with enterprise resource planning systems, supply chain networks, and customer feedback loops.

DXC is invaluable for manufacturers who can't just throw decades of existing infrastructure into a dumpster and start fresh (which, let's be honest, is most manufacturers). Their solutions put security front and center, which matters when you're connecting critical manufacturing systems to the cloud. You can read more about their approach.

2. Siemens

Siemens brings decades of industrial automation experience into the IoT era, and they're not messing around. Their MindSphere platform connects everything shop floor equipment, building management systems, probably the coffee maker in the break room creating digital twins that mirror physical operations in real-time.

Siemens works closely with NAMUR, the organization setting automation standards for chemical and pharmaceutical industries. This partnership ensures their solutions prevent unexpected shutdowns at highly automated plants, where downtime doesn't just cost money it costs millions per hour.

3. Hitachi Vantara

Hitachi Vantara approaches manufacturing IoT through the lens of data intelligence and AI, which sounds fancy because it is. Their Lumada platform crushes massive data volumes from every conceivable source, using machine learning to spot patterns that would make a human's eyes glaze over in approximately three seconds.

Hitachi focuses on merging operational technology with information technology breaking down those traditional walls between production systems and business intelligence.

4. Rockwell Automation

Rockwell built their reputation on industrial control systems and evolved into a full-stack IoT solutions provider. Their FactoryTalk platform creates what they call the 'Connected Enterprise' linking production, maintenance, supply chain, and business systems into one happy (or at least functional) family.

Rockwell kills it in the food industry, where traceability, quality control, and regulatory compliance demand obsessive data management. Nobody wants a repeat of the 2008 salmonella outbreak that nearly destroyed the peanut butter industry, so yeah, this stuff matters.

5. Schneider Electric

Schneider Electric stands out by making sustainability the centerpiece of their IoT strategy rather than an afterthought mentioned in ESG reports. Their EcoStruxure platform doesn't just optimize manufacturing efficiency, it specifically targets energy consumption and environmental impact.

Schneider works with industries facing brutal environmental regulations (looking at you, European manufacturers), helping them track emissions in real-time and optimize resource usage. Because nothing motivates quite like hefty government fines.

The Brain Behind the Machines: How IoT is Transforming the Factory Floor

The old manufacturing mantra was 'if it ain't broke, don't fix it.' Smart manufacturing IoT basically took that wisdom, set it on fire, and replaced it with 'fix it before it breaks.' This shift from reactive to predictive maintenance seems subtle, but it's absolutely revolutionizing how factories operate.

BMW provides a textbook example. Their manufacturing facilities use IoT platforms to babysit every piece of equipment on assembly lines. Sensors track vibration patterns, temperature swings, energy consumption, basically anything that moves or makes noise. When metrics start drifting from normal, algorithms predict potential breakdowns days or weeks ahead. This approach has cut unexpected downtime by up to 50%, which in automotive manufacturing translates to 'that's an eye-watering amount of money.'

The beautiful reality of predictive maintenance:

- Scheduled maintenance during slow periods instead of emergency repairs at 3 AM

- Ordering parts with normal shipping instead of paying $500 for overnight delivery

- Performing work during planned windows instead of scrambling with all hands on deck

- Actually sleeping through the night without panic calls about production lines

Shell, operating in oil and gas (where mistakes tend to make international headlines), leads the pack in implementing IIoT for monitoring rotating equipment like pumps and compressors. They lean hard into machine learning for predicting failures based on vibration, temperature, and other parameters. In an industry where an unexpected breakdown can mean environmental catastrophes and financial losses that make your mortgage look cute, predictive maintenance isn't optional, it's survival.

Here's some perspective: Henry Ford revolutionized manufacturing with the moving assembly line in 1913, cutting Model T production time from 12 hours to 93 minutes. That was automation 1.0, impressive for its time, revolutionary even. Today's factories learn from their mistakes, automatically adjust processes, and continuously optimize themselves. Ford would probably need a moment to process that.

From Waste to Wisdom: Real Business Benefits of IoT

Let's talk cold, hard numbers, because that's what actually matters to the folks signing checks for technology investments. IoT in smart manufacturing delivers benefits you can actually measure, not just marketing fluff.

Coca-Cola deployed IoT sensors on bottling lines to monitor temperature, fill levels, and quality parameters in real-time. The system catches problems in seconds, not hours after thousands of bottles have already rolled off the line. Result? Fewer defective products, fewer embarrassing recalls, consistent quality, and customers who don't tweet angry things about their flat Coke.

Energy consumption represents a massive chunk of manufacturing costs the kind that makes CFOs break out in cold sweats. IoT systems detect inefficiencies that operators never notice: motors running for no reason, heating systems overcompensating, compressed air leaking like a sieve. One auto parts manufacturer discovered through IoT monitoring that 30% of their energy costs came from equipment idling overnight. Thirty percent! That's like leaving every light in your house on while you're on vacation, except industrial-scale.

More factories are deploying IoT sensors to track emissions and energy consumption in real-time. This isn't just about feeling good, it's about meeting increasingly strict regulations while identifying sneaky sources of waste. IIoT is making manufacturing greener, whether executives care about polar bears or just avoiding fines.

Key Use Cases That Actually Work

Predictive Maintenance at Scale

General Motors slashed downtime by 30% after rolling out comprehensive IoT monitoring. They track everything: robotic arm performance, paint booth conditions, probably the humidity in the bathrooms. GM estimates this saves them tens of millions annually the kind of money that makes board members smile.

General Electric and their Predix software were early evangelists for IIoT, back when most people thought IoT were a typo. Their solutions monitor gas turbines and other critical equipment at power plants and refineries, preventing the kind of downtime that costs millions and makes it onto CNBC.

Asset Tracking and Logistics

Honeywell deployed IoT sensors for real-time logistics tracking throughout entire supply chains. Every pallet, every container gets monitored from supplier to shop floor. This visibility eliminates classic manufacturing nightmares, production lines grinding to a halt because some $50 part is stuck in traffic somewhere between Shenzhen and Cincinnati.

Quality Control and Defect Detection

Intel integrated AI with smart manufacturing IoT to catch microchip defects that would sail past human inspectors. Semiconductor manufacturing demands near-perfect precision — we're talking tolerances measured in nanometers. Their system uses high-resolution cameras paired with machine learning algorithms, working 24/7 without coffee breaks or declining eyesight.

Conclusion: The Future of Smart Manufacturing IoT

From Rolls-Royce jet engines to that perfectly consistent Coca-Cola flavor, IoT already weaves through modern manufacturing like a digital nervous system. It's no longer a 'future tech,' it's the new baseline for survival.

Fast forward five years, and factories will learn on their own, 3D-print their own parts, and maybe even relocate to Mars. Digital twins will replace blueprints, and holographic control panels will take over from traditional screens.

Companies that have already embraced smart manufacturing IoT are seeing double-digit productivity boosts and massive cost reductions. Those still 'thinking about it' risk becoming the next Blockbuster in a Netflix world.

And yes, the future is closer than it looks, even the office coffee machine might get a software update before some production systems do. So the real question isn't 'Should you implement IoT?' but 'Will you have time to implement IoT before your competitors have already switched to a new technology saber and moved their production to Mars?'

© Copyright IBTimes 2025. All rights reserved.