Scientists hack off-the-shelf 3D printer to allow it to bioprint tissue suitable for heart repair

US scientists have been able to hack a standard 3D printer to print tissue to repair damage organs, at a much cheaper rate than bioprinters. Researchers from the Carnegie Mellon University have developed a 3D-printing method that can assemble common tissue which could potentially be used, rather than opting for an organ transplant – which often comes with lengthy delays, especially in the US where 4,000 people are waiting for a heart transplant.

Adam Feinberg, an associate professor of Materials Science and Engineering and Biomedical Engineering at Carnegie Mellon University, said: "We've been able to take MRI images of coronary arteries and 3D images of embryonic hearts and 3D bioprint them with unprecedented resolution and quality out of very soft materials like collagens, alginates and fibrins."

Furthermore, the team were able to do this using printers that can be bought in a shop for as little as $1,000 (£652), whereas bioprinters can cost up to $100,000. "Not only is the cost low, but by using open-source software, we have access to fine-tune the print parameters, optimise what we're doing and maximise the quality of what we're printing," Feinberg said. "It has really enabled us to accelerate development of new materials and innovate in this space. And we are also contributing back by releasing our 3D printer designs under an open-source licence."

Standard 3D printers have so far been limited to creating hard objects, using plastics and metals by creating layer upon layer on to a surface to create the object. Using softer materials, such as gels, has proved to be difficult so far as it is tricky to create the supportive base.

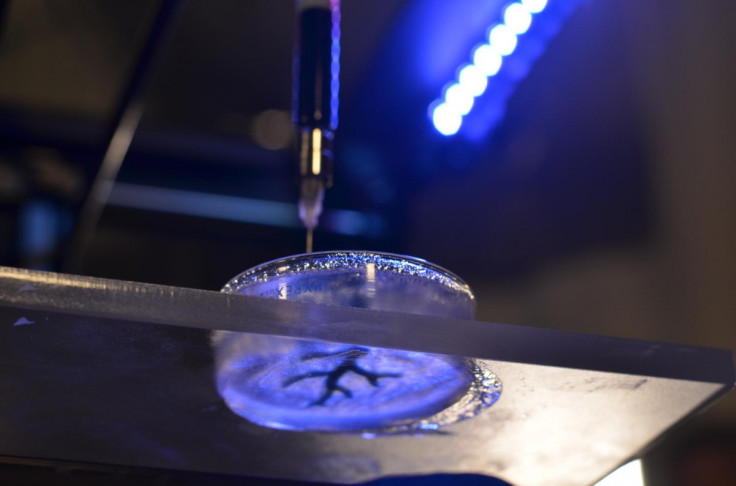

Feinberg added: "The challenge with soft materials – think about something like Jello that we eat – is that they collapse under their own weight when 3D printed in air. So we developed a method of printing these soft materials inside a support bath material. Essentially, we print one gel inside of another gel, which allows us to accurately position the soft material as it's being printed, layer-by-layer."

A new technique known as Fresh (Freeform Reversible Embedding of Suspended Hydrogels) has been created, which allows support gels to be melted away within the body, and is not harmful when it disappears. This has allowed the researchers to build a 3D-designed sturdy structure, which becomes more malleable and fluid once it is in the host.

© Copyright IBTimes 2025. All rights reserved.