3D-Printed Lens Turns Smartphones Into a £1 Microscope to Detect Diseases

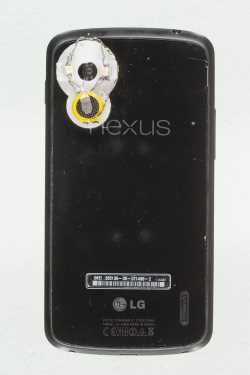

Australian National University (ANU) researchers have used a 3D-printed lens and a Nexus 4 smartphone to create a £1 microscope that can detect skin diseases almost as well as a £300 clinical microscope.

At the moment, conventional lenses are made by either grinding or polishing a flat disk of glass into a particular curved shape – the same way lenses have been made since the 18<sup>th century – or by pouring gel-like materials into moulds.

Droplets of clear water are able to bend light and therefore able to act as a lens. The researchers decided to exploit this phenomenon to see just how good a lens they could make.

Imitating the nature of water droplets

To do this, they placed several drops of a common gel-like silicone polymer called polydimethylsiloxane (PDMS) onto a microscope glass slide and then baked the drops in an oven at 70 degrees Celsius to harden it.

Once a hard base is formed, another drop of PDMS is added on top of the base, and then the whole microscope slide is flipped over.

Gravity causes the new drop to pull downwards and form a parabola, i.e. a 2D, mirror-symmetrical downwards curve, and then then it is baked again to solidify the lens in that shape.

Using this method, the researchers were able to produce lenses offering a magnification power of 160 times and a resolution of about 4 microns (millionths of a metre).

When they attached the lens to a Nexus 4 smartphone, together with two LEDS to angle the light and a watch battery, the researchers were able to produce a dermascope able to diagnose skin diseases like melanoma.

3D-printed dermascope costing just £1

"What I did was to systematically fine-tune the curvature that's formed by a simple droplet with the help of gravity, and without any moulds," said Steve Lee from ANU's Research School of Engineering.

"It's a low cost and easy lens-making recipe. I'm really excited that it opens up lens fabrication technology."

Of course the resolution of the £1 microscope is not as high in optical resolution as a clinical microscope which costs almost £300, but as it is, it would be more than suitable for hobbyists, children or those in rural areas and developing countries.

So successful is their invention that a new dermascope product is now being produced using a 3D printer and will be commercially available later this year.

The results of the researchers' findings have been published in a study entitled, "Fabricating low cost and high performance elastomer lenses using hanging droplets" in open-access journal Biomedical Optics Express.

© Copyright IBTimes 2025. All rights reserved.