Stratasys CEO: Digital Factories of the Future Will Use 3D Printers With Tech-Savvy Workers

3D printers will revolutionise manufacturing industry, promises 3D printing boss

Forget everything you know about factories and manufacturing today and imagine a world where you are a business, but you never have to travel overseas to build your factory. You have no middle-men, you do everything by yourself in-house, and it does not cost the Earth or hurt the environment.

This dream world is the vision 3D printer company Stratasys is touting: a world where 3D printing does not just disrupt manufacturing, but becomes manufacturing.

Stratasys began in 1989 and has been developing 3D printing, also known as "additive manufacturing" or "rapid prototyping", for the last 25 years.

From initially offering to print out items in just 35 materials, the company is now a multi-national corporation selling its own lines of desktop and industrial 3D printers, and specialised 3D-printing services, using more than, 1,200 materials to customers.

The customers they work with are from a wide range of industries – including medical, dental automobile, race cars, aerospace and movie-making – that use traditional manufacturing methods, but are increasingly turning to 3D printing for their needs.

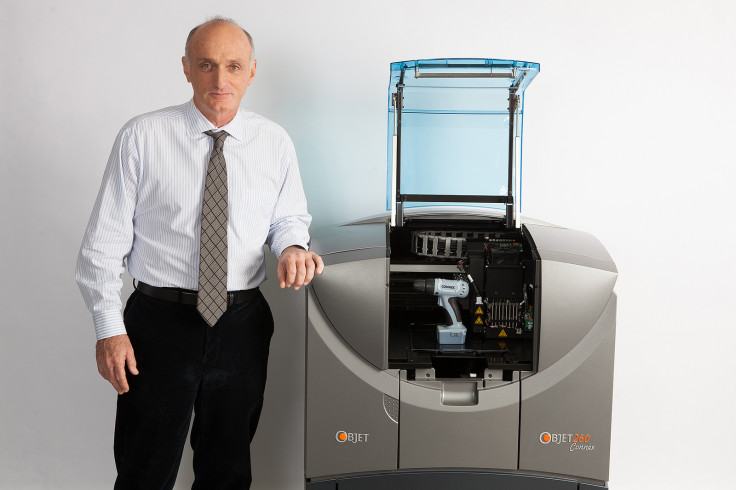

"Manufacturing is a huge market. [3D printing] in the near future is going to be suitable to areas in the manufacturing world that have a need for short-run manufacturing or very customised products," Stratasys chief executive David Reis told IBTimes UK.

"In those segments, we are going to see factories that are totally digital, so full replacement of traditional production methods like injection moulding and CNC machining [a process that uses computers to control machine tools]."

Not only that, factory workers of the future will need to be much more tech-savvy. They will have to be comfortable with taking data about an object, building and manipulating it into a 3D model in CAD software, and understand how to make adjustments to it within the software.

"It's a different skill-set. It will require [factory workers to have] an understanding of software, additive manufacturing and material technology," said Reis. "It will create a lot of jobs, just in different areas to today."

IT research and advisory company Gartner says that worldwide shipments of 3D-printed products will increase by 107% between 2014 to 2015, and by 2018 there will be over 2.3 million shipments a year.

This will be partly due to start-ups and other small companies starting to sell consumer 3D printers at a much lower entry price of under $500 (£312), but Stratasys is likely to see competition by other big electronics players.

Just this week, HP entered the market with a large industrial "multi-jet fusion" 3D printer that it claims is 10 times faster than other models in its sector.

However, Stratasys has another trick up its sleeve. Alongside its plan to make factories digital, it also wants to help traditional manufacturers keep going by speeding up their production processes.

"There's not necessarily a compelling use case for the home – more in education – but I can think of a use of 3D printers in almost every industry."

- Pete Basilier, Gartner

To do this, the firm is encouraging manufacturers to embrace augmented manufacturing, whereby important specialised tools, jigs and fixtures (for example, a robot arm used to put together components) that are used in the manufacturing process can be 3D printed in a few hours, rather than spending weeks to have a gadget tooled.

These tools might not last as long as traditionally tooled jigs and fixtures, but they will help to speed up the product cycle significantly and are cheap and quick to replace.

"By using augmented manufacturing, companies are able to accelerate time to market on new products, as well as enabling superior product characteristics. This allows for mass customisation and new business models," says Reis.

"Stratasys keen to expand into digital manufacturing, first with jigs and fixtures, eventually into end user parts."

But what about the consumer market? Both Reis, and Gartner analyst Pete Basiliere are sceptical that there will be a 3D printer in every home one day.

"I don't see a 3D printer being in every home. There's not necessarily a compelling use case for the home – more in education – but I can think of a use of 3D printers in almost every industry. There's a steady improvement in all the technologies in this space," Basiliere told IBTimes UK.

"Rapid prototyping has been core to the success of the industry and it's not going away. Now the next step is this augmented manufacturing."

© Copyright IBTimes 2025. All rights reserved.