Lockheed Martin to 3D Print Satellites and Spacecraft Components to Cut Costs

Aerospace and advanced technology maker Lockheed Martin says the next decade could see satellites being completely made from 3D printing and virtual reality avatars used to solve problems, as the company looks to cut costs in an ever-changing market.

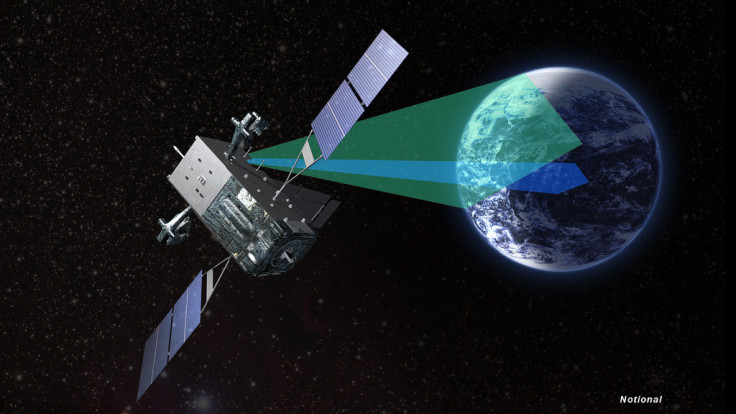

Lockheed Martin is the leading supplier of advanced military technology like missile-warning satellites to the Pentagon, but now the US Air Force is trying to open the market to more competition and the US government has cut defence spending.

To combat this, the weapons-maker is looking at 3D printing, which it believes could reduce the weight of key components on spacecraft, which would enable more sensors to be included and enable governments to launch satellites on smaller, cheaper rockets.

3D-printed satellite components

Parts of Lockheed Martin's A2100 commercial satellites have been made using 3D printers, and the Juno spacecraft currently being used by NASA's Juno Mission orbiting Mars carries a 3D-printed part in it.

"In the next decade, we will completely change the way a satellite is designed and built," Lockheed vice-president and general manager of military space Mark Valerio told Reuters.

"We will print a satellite. It's real. We're flying it on satellites now."

At the moment, it costs over $1 billion (£593m) to build a big satellite as they are not ordered in large volumes. Over 60% of its satellites are currently made by third party suppliers, so Lockheed Martin is also looking at making satellite components in-house from a 3D printer.

Virtual reality avatars

The weapons manufacturer is also making use of virtual reality human avatars to help work through challenges and streamline production processes.

In 2011, Lockheed saved $150 million and lots of re-testing by using its virtual reality and simulation laboratory to brainstorm a method to replace a malfunctioning circuit card on a Space-Based Infrared System (SBIRS) satellite.

The company is also using virtual reality to cut the number of times its new batch of Global Positioning System (GPS) satellites have to be lifted during manufacturing by 64%.

"We're trying to find new ways of doing things. We're leaving no stone unturned," said Valerio.

Elon Musk's SpaceX has been using a 3D laser metal printer to print out spacecraft components since 2012, and last year Nasa 3D-printed a rocket injector that outperformed non-printed injectors with an impressive record-breaking 22,000 pounds of thrust.

Nasa is also working together with start-up Made in Space to deliver a 3D printer to the International Space Station this autumn in order to test how well it works in zero gravity.

© Copyright IBTimes 2025. All rights reserved.