1D printing: These shape changing robots can easily go through hard-to-reach spots

The system immediately creates shape changing 1D bots to perform locomotion tasks.

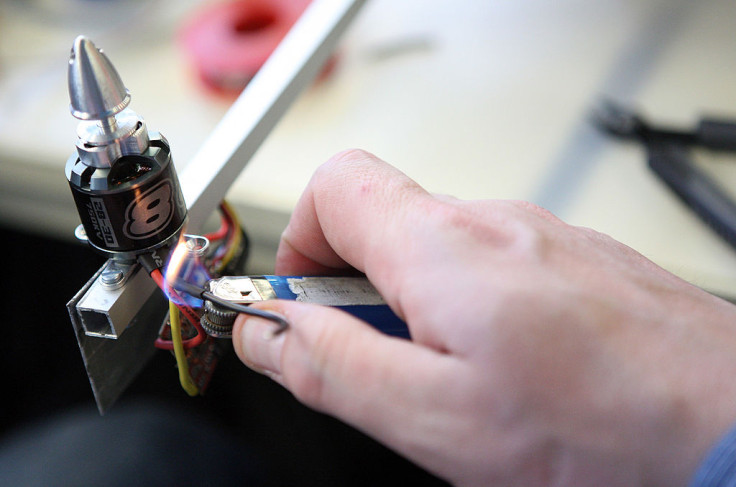

In a breakthrough development, researchers at the IT University of Copenhagen have coined a unique 1D printing system that bends a wire with motors attached into different shapes so that it could fit into any crevice or crack to deal with simple locomotion tasks or something as bothering as picking up a tiny object from a hard-to-reach spot.

This proof-of-concept system involves both a novel manufacturing platform that configures the wire using folding and a computational optimisation tool that changes its shape bit-by-bit until it gets the form needed to get the job done. You just have to analyse the situation and enter constraints into the software so that it could work something out accordingly.

As New Scientist reports, the design of the transformer robot keeps on evolving, but it's not necessary that the system will find the best shape on the very first attempt. No matter what the task is, it could still take some time to satisfy all the constraints perfectly.

And once the intended goal has been accomplished, you can simply recycle the wire back into the machine to produce new designs for a different project.

Sebastian Risi, a member of the research team, said, "The idea is that you analyse the current situation, then make a robot on the fly that can deal with it".

"You then end up with a robot that can crawl under that awkward piece of rubble or over collapsed wall in a burning building. They are cheap and easy to make, and afterwards you can easily recycle them or just make a new one," Risi added.

Risi and his teammates, who are now working to augment these bots with cameras and microphones, believe their system could prove handy in space and rescue missions where an instead of 15, a single 1D bot could be immediately created and recycled to do different things.

© Copyright IBTimes 2025. All rights reserved.