Scientist invents 3D printing technology for Nasa that makes it possible to print objects on Mars

A scientist has developed a brand new 3D printing material that combines soil on Mars with ceramics to create a material that stands high temperatures, making it possible for objects and structures to be fabricated on the red planet using whatever resources are at hand.

It is still very expensive to launch and ship cargo into space, and just to launch 1kg of cargo costs $10,000 into low Earth orbit, and $100,000 to launch it to the Moon, so at the moment, the amount of stuff that would need to be shipped to Mars means it is presently impossible to colonise the red planet.

So Nasa has set a range of challenges dedicated at finding ways to design and build habitats suitable for humans on Mars that use only surface materials that already exist on the red planet, and in September 2015, an ice house 3D printed from plastic and water was picked as the best solution.

But alongside developing new ways to build habitats, Nasa has also been keen for scientists and engineers to come up with new ways to easily construct objects and structures for both space and Earth.

Selective Separation Sintering

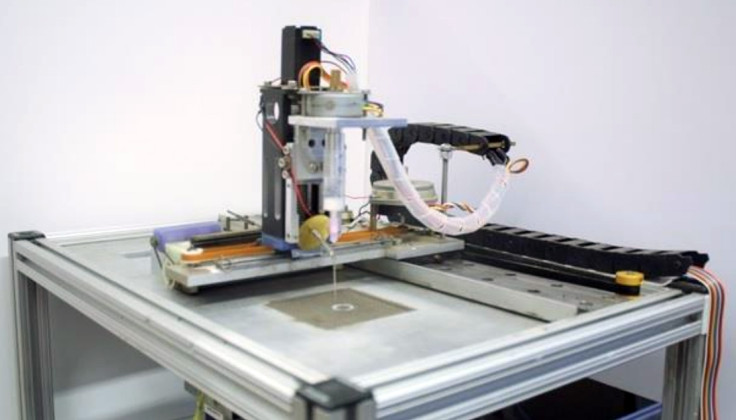

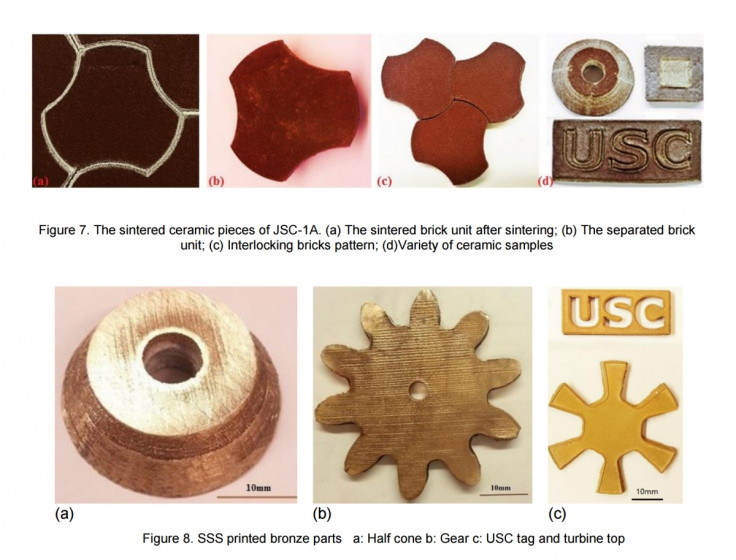

To that end, Dr Behrokh Khoshnevis, Director of the Center for Rapid Automated Fabrication Technologies (CRAFT) at the University of Southern California has developed a new 3D printing technology called Selective Separation Sintering (SSS) that combines gravel and soil found on Mars and the moon with high melting point ceramics like magnesium oxide to create a new material that is strong enough to withstand incredibly high heats.

Apart from habitats, colonising Mars will require us to build infrastructure such as roads, landing pads, radiation shields and blast walls. In 2014, Khoshnevis won an award for developing Contour Crafting, a technology whereby gigantic 3D printers can build large scale structures.

By combining Contour Crafting with SSS, astronauts will be able to print out both small and large objects, such as bricks, interlocking tiles or metallic components, which is just what you need to create a Martian city.

First method to work in zero gravity conditions

"It could make space pioneering more cost-effective and feasible. There are no viable, direct, high temperature metal, ceramic or composite fabrication methods that can work in zero-gravity conditions. SSS will be the first such process," said Khoshnevis.

"There is high potential for the space and planetary use of this technology. SSS is a minimally complex but highly capable technology that can effectively assist planetary exploration, utilisation and colonisation."

The open-access paper, entitled "Selective Separation Sintering (SSS) A New Layer Based Additive Manufacturing Approach for Metals and Ceramics", is available on the 2016 Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference website.

© Copyright IBTimes 2025. All rights reserved.