Scientists aim for flexible gadgets in five years after graphene OLED breakthrough

For the first time, scientists have been able to replace OLED electrodes with flexible graphene.

Researchers in South Korean claim to have crossed a significant milestone in bringing bendable gadgets to market after using graphene to create OLED display technology. Scientists at South Korea's Electronics and Telecommunications Research Institute (ETRI) suggested that the breakthrough could see flexible OLEDs commercialised within the next five years.

The transparent electricity-conducting material in OLED panels is typically made out of indium tin oxide, or ITO. While ITO is versatile it's also fragile, making it unsuitable for high degrees of flexing and bending.

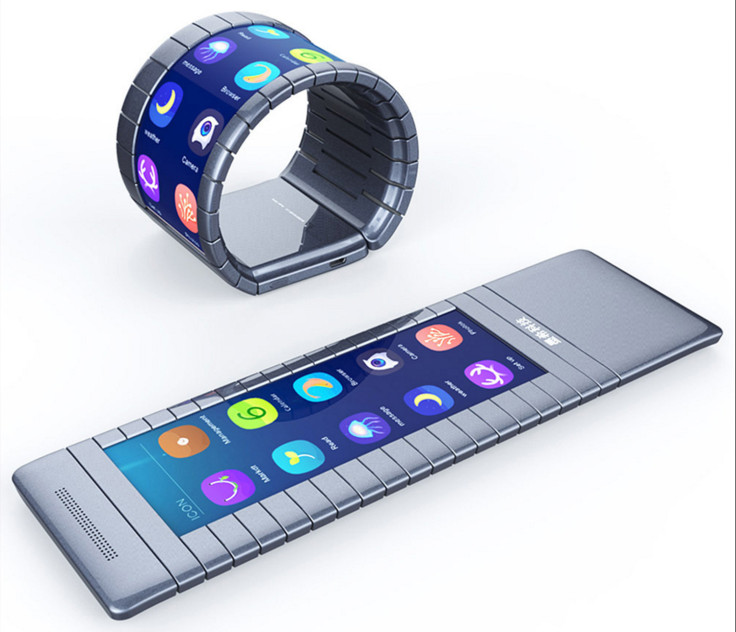

Researchers from ETRI developed a means of replacing ITO in OLED screens with transparent graphene. Graphene is much stronger than current materials used in OLED panels and is also highly malleable, opening up new possibilities for consumer gadgets, clothing and accessories sporting flexible or even foldable displays.

Graphene is frequently referred to as a "wonder material" due to its huge versatility, with potential applications ranging from more powerful batteries and faster computers to rocket propulsion systems and even a means of turning seawater into clean drinking water.

Despite being a fraction the diameter of a human hair, graphene is approximately 200 times stronger than steel, making it one of the strongest materials known to man.

According to The Korea Herald, ETRI scientists replaced ITO electrodes inside an OLED panel measuring 370nm thin with graphene electrodes just five nanometres thin, claiming to be the first team to pull off such a feat.

Commenting on the research, which was conducted in partnership with military technology and aeronautics firm Hanwha, a spokesperson from LG Display said: "If commercialised soon, the graphene electrode technology would help the industry achieve foldable panels significantly."

German researchers this week announced they have developed a means of ''drawing'' electronic circuits onto any surface with a new type of ink, potentially providing an inexpensive means of manufacturing flexible printed circuits.

© Copyright IBTimes 2025. All rights reserved.